The Definitive Ultimate Guide to Finding the Best 3D Printing Machine for Your Business Needs

In the rapidly evolving landscape of manufacturing, the demand for 3D printing machines is surging, driven by their ability to revolutionize production processes and enhance design innovation. According to a report from Grand View Research, the global 3D printing market is expected to reach $62.79 billion by 2028, growing at a CAGR of 21.0% from 2021 to 2028. This explosive growth underlines the significance of selecting the right 3D printing machine tailored to specific business needs. Whether you're in aerospace, healthcare, or automotive industries, the right machine can not only optimize production efficiency but also reduce costs and lead times. As companies look to adopt this transformative technology, understanding the nuances of different 3D printing machines is crucial for gaining a competitive advantage and meeting the ever-growing market demands.

Understanding Your Business Requirements for 3D Printing Solutions

When seeking the ideal 3D printing machine to fulfill your business requirements, it is essential to first understand the specific needs of your operations. Different industries, whether it's manufacturing, healthcare, or education, have unique demands that influence the choice of 3D printing technology. For instance, a medical facility may prioritize precision and biocompatibility in its printers, while a fashion brand might look for printers that can produce intricate and aesthetically pleasing designs. Conducting a thorough analysis of your current processes and future objectives can help streamline this decision-making.

Additionally, consider the scale of production and the materials needed for your projects. Factors such as printing speed, build volume, and material compatibility can significantly affect your productivity and the quality of the end product. Engage with your team to gather insights on how 3D printing can enhance workflows and meet customer expectations. By aligning the capabilities of various 3D printers with your business objectives, you can ensure that your investment not only meets today's demands but also adapts to future growth and innovation.

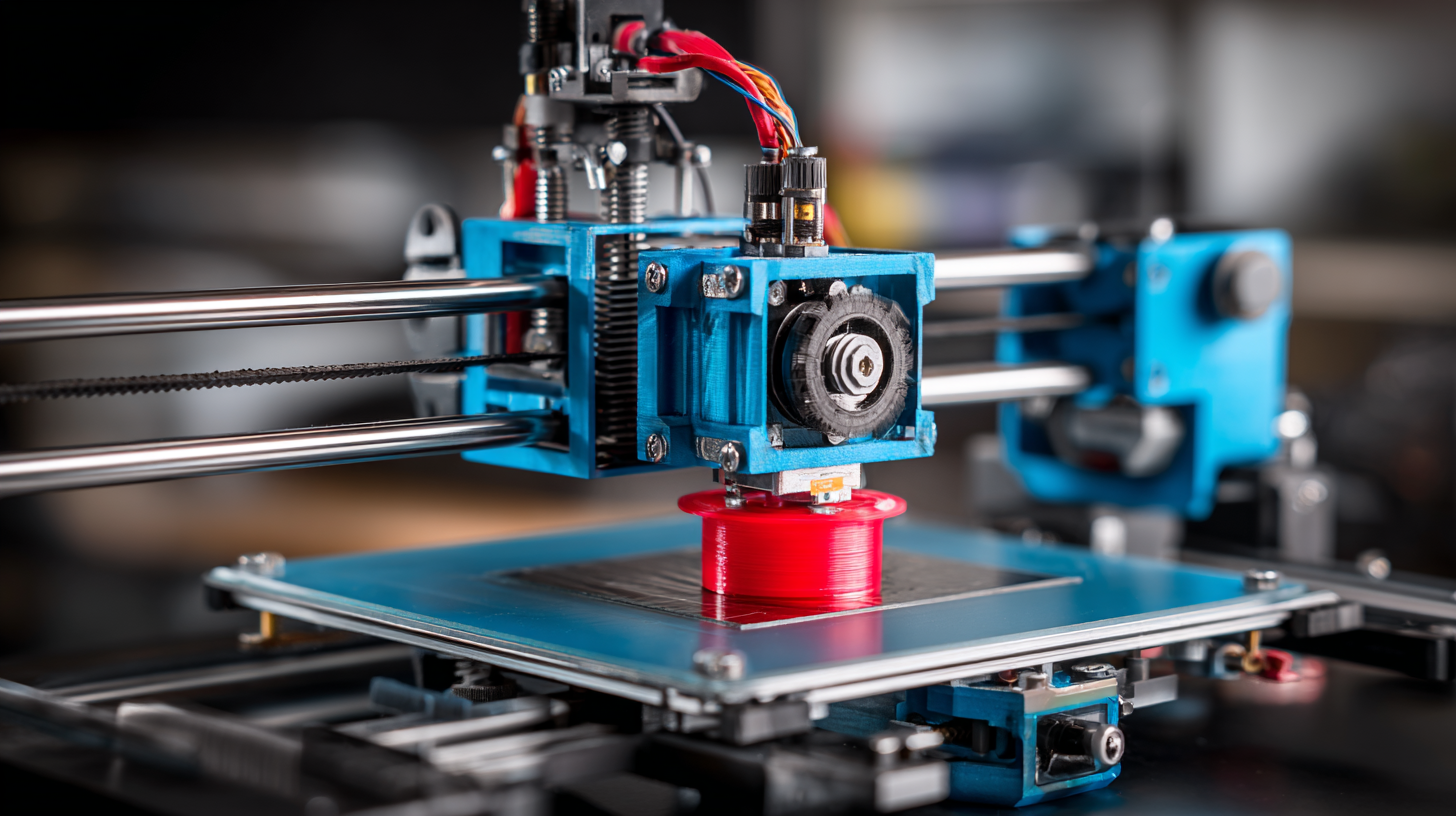

Key Features to Look for in a 3D Printing Machine

When searching for the best 3D printing machine to meet your business needs, focusing on key features is essential. First and foremost, print quality should be at the top of your list. Look for machines that offer high resolution and precision, as these factors directly affect the final product's appearance and performance. Additionally, consider the variety of materials the printer can handle, including plastics, metals, and composites. A versatile machine will enable your business to explore a broader range of applications and innovations.

Another critical feature is the build volume. Depending on your projects, a larger build volume allows for the creation of bigger items or multiple smaller components simultaneously. It’s also important to examine the software compatibility of the 3D printing machine. User-friendly software that easily integrates with your design tools will enhance your workflow and reduce production time. Lastly, consider the machine's reliability and the support offered by the manufacturer; having a robust support system can save you from lengthy downtimes and costly repairs down the line. By prioritizing these features, you can ensure that your investment in 3D printing technology will serve your business well.

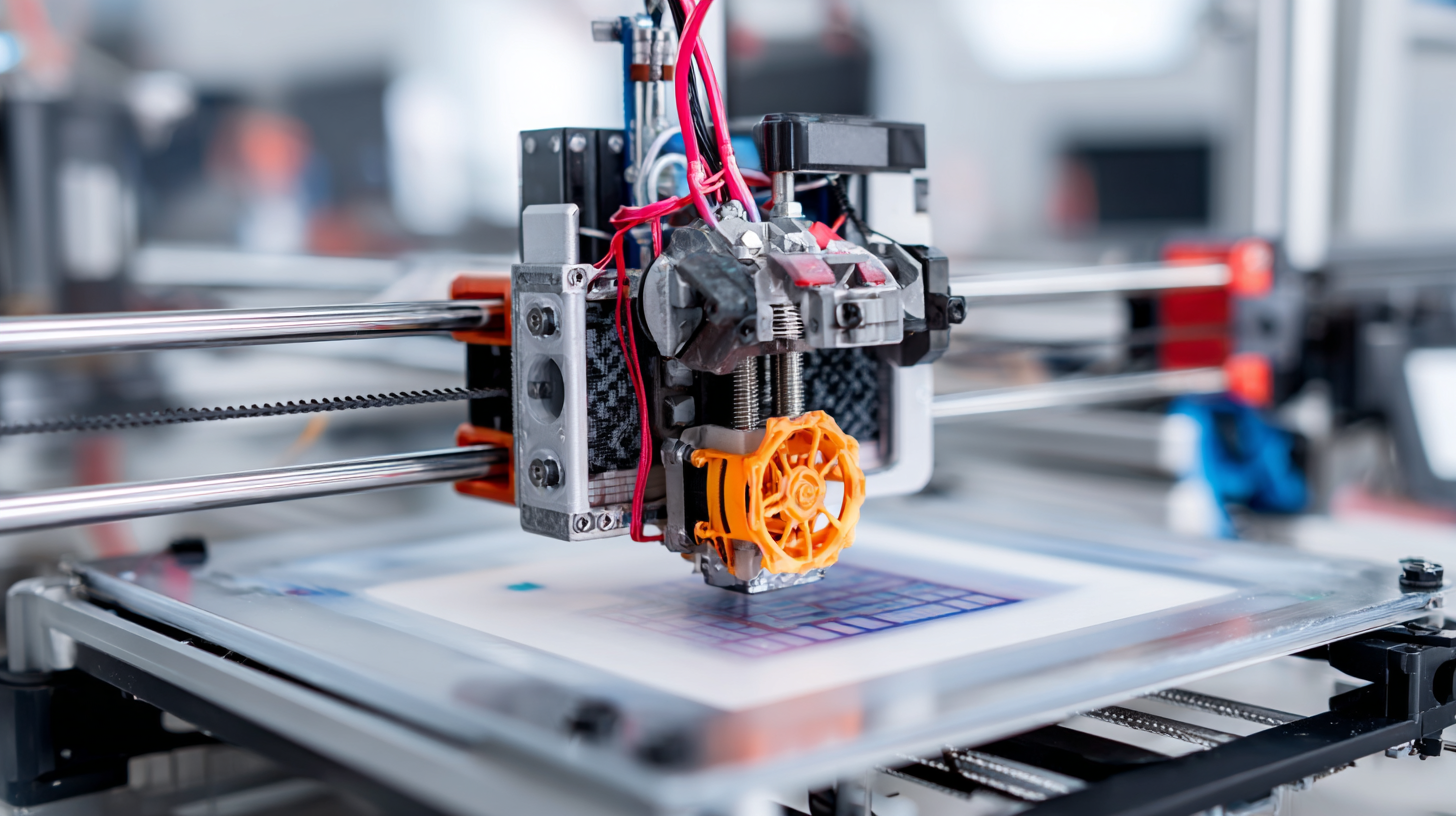

Comparing Different Types of 3D Printers: FDM, SLA, and SLS

When considering the right 3D printing technology for your business, it's essential to understand the differences between

Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). According to a report by MarketsandMarkets,

the global 3D printing market is expected to grow from $13.7 billion in 2020 to $34.8 billion by 2026,

with FDM holding a significant portion of the market share due to its affordability and ease of use. FDM printers utilize thermoplastic filaments, making them ideal for

prototyping and small-scale production, particularly in industries like education and automotive.

On the other hand, SLA technology is known for its precision and smooth surface finishes, which are vital in industries such as

dentistry and jewelry. Research by Wohlers Associates highlights that SLA is experiencing a resurgence as companies seek more detailed prototypes. Meanwhile, SLS stands out for its

ability to produce complex geometries and durable parts using powdered materials, which is especially beneficial in the aerospace and medical sectors. As the 3D printing

landscape continues to evolve, understanding these technologies will help businesses make informed decisions about their manufacturing processes.

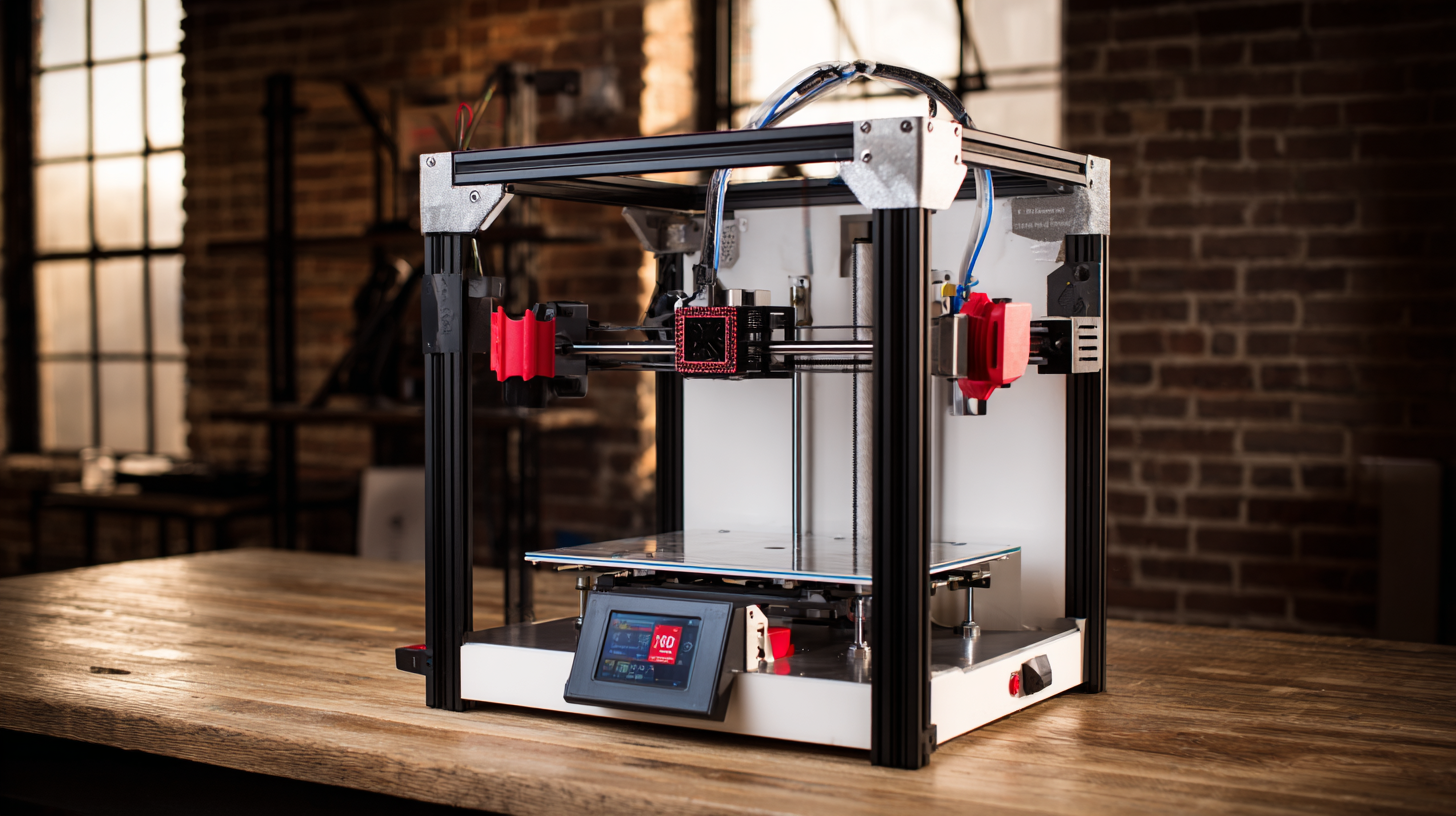

Budgeting for Your 3D Printing Investment: Costs and Financing Options

When considering the purchase of a 3D printing machine, budgeting becomes a crucial element of the decision-making process. The initial costs can vary widely based on the machine’s capabilities, intended use, and brand reputation. It’s important to assess not only the upfront expenses but also the ongoing operational costs such as materials, maintenance, and potential upgrades. By creating a detailed budget, businesses can ensure they choose a machine that aligns with their financial capacity while meeting their production needs.

Financing options can further ease the burden of this investment. Many manufacturers and suppliers offer flexible payment plans, leasing agreements, and even financing through third-party lenders. These options allow businesses to spread out the cost over time, making high-quality 3D printing technology more accessible. It’s essential to evaluate the terms of each financing option, including interest rates and duration, to find a plan that won’t strain your business’s cash flow. Taking the time to explore these financial opportunities can significantly impact the overall success of integrating 3D printing into your operations.

The Future of 3D Printing Technology: Trends to Watch for Your Business

As we venture further into the realm of technological innovation, the future of 3D printing technology holds immense potential for businesses across various sectors. One of the most significant trends is the rise of eco-friendly materials. Businesses are increasingly seeking sustainable printing options, leading to the development of biodegradable and recycled filaments. This shift not only addresses environmental concerns but also appeals to consumers who prioritize sustainability in their purchasing decisions.

Another crucial trend to monitor is the integration of artificial intelligence and machine learning into 3D printing systems. These advancements enhance the efficiency and accuracy of the printing process, allowing for rapid prototyping and customization of products to meet specific customer needs. As AI continues to evolve, businesses will be able to streamline production, reduce waste, and improve turnaround times, making 3D printing an even more attractive option for manufacturers. Adopting these innovations will enable companies to remain competitive and responsive to market changes.

The Definitive Ultimate Guide to Finding the Best 3D Printing Machine for Your Business Needs

| 3D Printer Type | Max Build Volume (mm) | Layer Resolution (µm) | Material Compatibility | Average Price (USD) |

|---|---|---|---|---|

| FDM | 300 x 300 x 400 | 100 - 300 | PLA, ABS, PETG | 1,500 - 3,000 |

| SLA | 145 x 145 x 175 | 25 - 100 | Resin | 2,000 - 5,000 |

| SLS | 250 x 250 x 300 | 80 - 100 | Nylon, TPU | 15,000 - 50,000 |

| DLP | 120 x 68 x 175 | 25 - 100 | Resin | 3,000 - 10,000 |