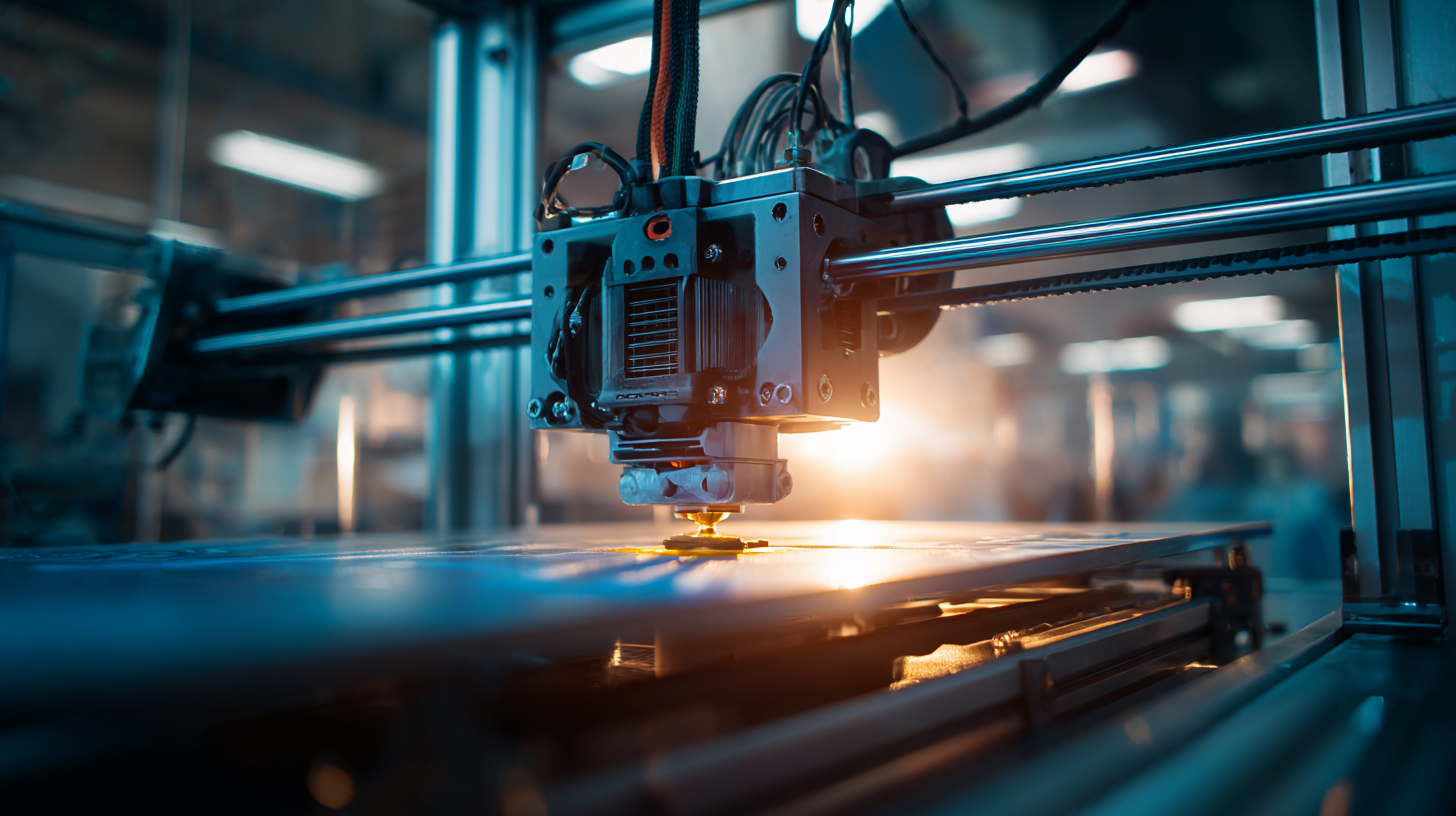

Exploring the Top Industrial 3D Printers for Global Buyers in 2023

As the demand for rapid prototyping and custom manufacturing continues to rise, industrial 3D printers have emerged as indispensable tools for businesses across various sectors. In 2023, a diverse array of industrial 3D printers is available on the market, each designed to cater to specific production needs and material requirements.

From fused deposition modeling (FDM) printers best suited for prototyping to subtractive and additive manufacturing solutions ideal for producing high-precision parts, understanding the unique features and applications of these devices is crucial for global buyers. This blog aims to explore the top industrial 3D printers currently on the market, offering insights into their characteristics, advantages, and the industries they best serve. Whether you're looking to enhance your manufacturing capabilities or dive into the world of additive manufacturing, this comprehensive guide will help you navigate the complex landscape of industrial 3D printing technologies.

From fused deposition modeling (FDM) printers best suited for prototyping to subtractive and additive manufacturing solutions ideal for producing high-precision parts, understanding the unique features and applications of these devices is crucial for global buyers. This blog aims to explore the top industrial 3D printers currently on the market, offering insights into their characteristics, advantages, and the industries they best serve. Whether you're looking to enhance your manufacturing capabilities or dive into the world of additive manufacturing, this comprehensive guide will help you navigate the complex landscape of industrial 3D printing technologies.

The Rising Demand for Industrial 3D Printers in Key Global Markets (2023)

The rising demand for industrial 3D printers is becoming a pivotal trend in key global markets, driven by the need for rapid prototyping and customization across several sectors. The global industrial 3D printing market, valued at approximately USD 2.4 billion in 2022, is projected to surge to USD 17.7 billion by 2033, reflecting an impressive compound annual growth rate (CAGR) of 21% from 2023 onward. This expansion is largely fueled by innovations in manufacturing processes and materials, which allow businesses to streamline production and reduce waste.

In the automotive sector, for instance, the 3D printing market is expected to reach USD 4.7 billion in 2023, growing at a CAGR of over 14.2% until 2032. Similarly, aerospace applications are seeing a significant market increase; the 3D printing market in this industry is estimated to grow from USD 9.2 billion in 2023 to USD 17.2 billion by 2030, achieving a CAGR of 9.3%. These figures underscore the versatility and efficiency that industrial 3D printing brings to design and manufacturing processes.

Tips: When considering investing in industrial 3D printing technology, assess the specific needs of your production processes and choose a printer that aligns with your operational goals. Additionally, keep an eye on emerging materials, such as polymers and metal alloys, as they can significantly enhance your product offerings. Lastly, understanding the market trends in sectors like automotive and aerospace can provide valuable insights for strategic planning.

Top Trends Shaping the Industrial 3D Printing Landscape This Year

The industrial 3D printing landscape in 2023 is marked by rapid growth and significant trends that are reshaping the market. According to recent reports, the U.S. smart manufacturing market is projected to grow from $66.18 billion in 2023 to $145.7 billion by 2030, with a compound annual growth rate (CAGR) of 11.9%. This growth is fueled by advancements in technology and an increasing demand for efficiency in manufacturing processes. Additionally, the desktop 3D printing market is expected to surge from $3 billion in 2023 to $9.5 billion by 2032, reflecting a robust CAGR of approximately 13.65% over the same period.

The dental 3D printing market is also experiencing remarkable expansion, with a market size exceeding $3 billion in 2023. It is anticipated to witness a CAGR of around 21.5% from 2024 to 2032, largely driven by the growing focus on reducing turnaround times and material waste in dental laboratories. Moreover, the growing interest in 3D-printed drones, projected to reach a market size of $16.49 billion by 2032, demonstrates a staggering CAGR of 39.38% from 2024 to 2032. This increase highlights the evolving applications of 3D printing technology, making it more accessible and affordable while expanding its practical uses across various industries.

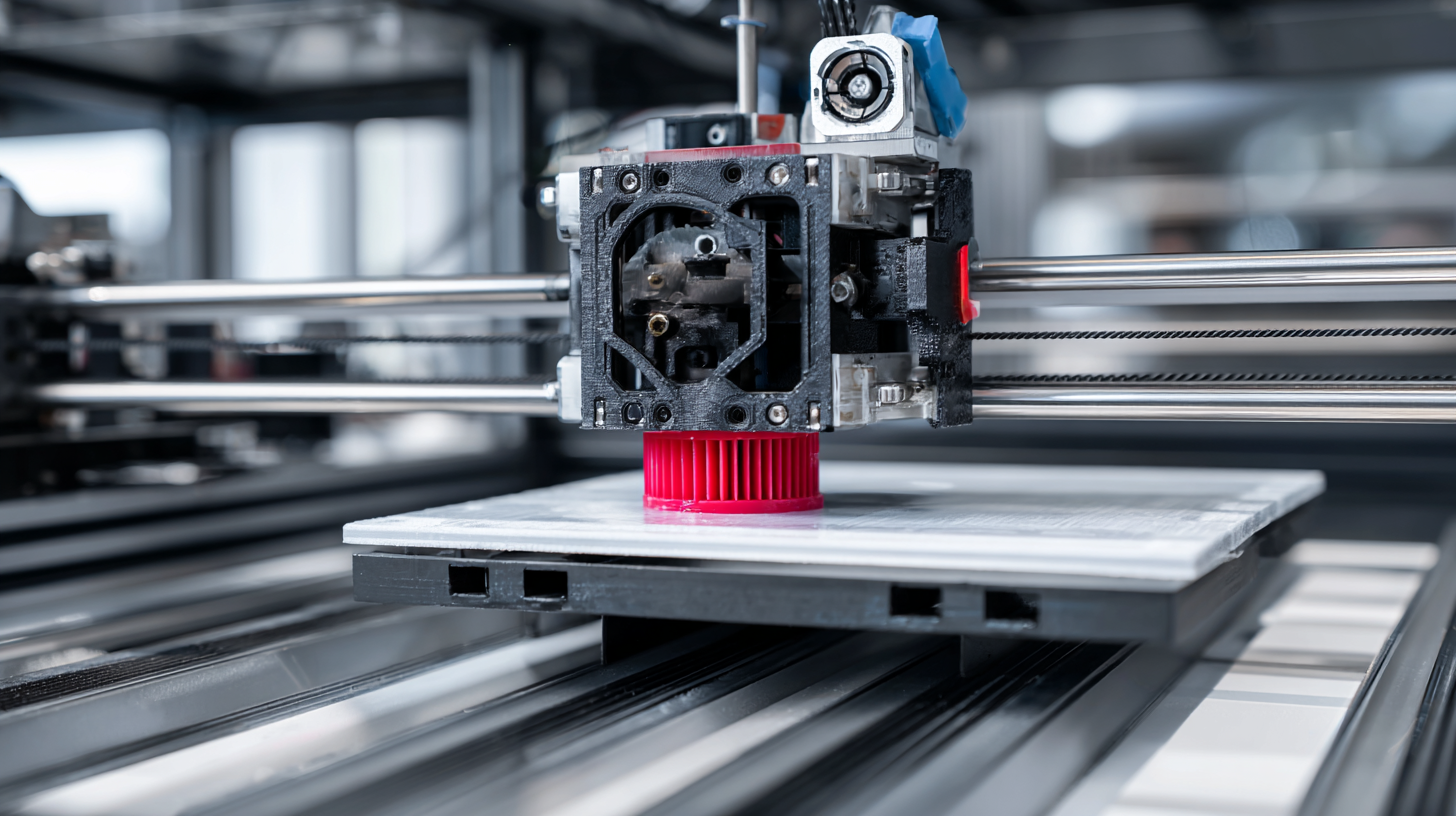

Comparative Analysis of Leading Brands in the Industrial 3D Printer Market

As the industrial sector continues to embrace the transformative potential of additive manufacturing, buyers are confronted with a myriad of options in 3D printers. With brands like Stratasys, EOS, and XYZprinting leading the charge, a comparative analysis of these market giants reveals distinct capabilities tailored to diverse applications. Stratasys stands out for its extensive material portfolio and superior printing technology, making it ideal for prototyping and production of complex geometries. Meanwhile, EOS excels in metal 3D printing, providing solutions that cater to industries such as aerospace and automotive where precision and strength are paramount.

Furthermore, emerging players like Ultimaker and Formlabs are making their mark by offering user-friendly interfaces and cost-effective solutions suited for smaller enterprises. Ultimaker's dual extrusion capabilities enhance flexibility, while Formlabs’ focus on resin printing yields exceptional detail and surface finish for intricate parts. By evaluating the strengths and weaknesses of these leading brands, global buyers can better align their investment decisions with their specific manufacturing needs, ensuring they harness the full potential of industrial 3D printing technology in 2023.

Comparative Analysis of Leading Industrial 3D Printers in 2023

Breaking Down the Cost vs. Benefit of Investing in 3D Printing Technology

The global dental 3D printer market is witnessing significant growth, driven by technological advancements and the increasing demand for precise dental solutions. By 2025, the market size is expected to reach approximately $280.41 million, with projections pointing to an impressive compound annual growth rate (CAGR) of 22.9%, indicating strong investment potential for stakeholders. This surge is largely attributed to the transition from traditional manufacturing methods to digital solutions, with processes such as intraoral scanning and CAD/CAM enhancing efficiency and accuracy in dental applications.

Furthermore, the broader 3D printing market is set to expand significantly, with the global 3D printed eyewear market estimated to grow from $156.27 million in 2025 to about $309.1 million by 2033, reflecting a CAGR of 8.9%. Such growth trends highlight the cost-effectiveness and versatility of 3D printing technology, prompting industries beyond dental to invest in additive manufacturing solutions. As companies weigh the costs against the benefits, it becomes clear that the shift towards 3D printing is not just a fleeting trend, but a strategic move that offers long-term value across multiple sectors.

Exploring the Top Industrial 3D Printers for Global Buyers in 2023 - Breaking Down the Cost vs. Benefit of Investing in 3D Printing Technology

| Model Type | Build Volume (mm) | Material Compatibility | Cost (USD) | Estimated ROI (Years) | Key Benefits |

|---|---|---|---|---|---|

| FDM Printer | 300 x 300 x 400 | PLA, ABS, PETG | $2,500 | 2.5 | Affordable, Versatile Materials |

| SLA Printer | 192 x 120 x 200 | Resins | $3,000 | 3.0 | High Accuracy, Smooth Finish |

| SLS Printer | 250 x 250 x 300 | Nylon, TPU | $10,000 | 4.0 | Strong Parts, No Support Structures |

| PBF Metal Printer | 200 x 200 x 200 | Stainless Steel, Titanium | $150,000 | 5.0 | Complex Geometries, High Strength |

| Binder Jetting | 300 x 300 x 400 | Metals, Ceramics | $100,000 | 3.5 | Fast Production, Low Material Waste |

Future Innovations to Watch: How 3D Printing Will Evolve Beyond 2023

As we venture into the future, the evolution of 3D printing technology is set to transform industries in ways we never imagined. Beyond 2023, we can expect significant advancements in the materials used, with biocompatible and sustainable options becoming more mainstream. These innovations will not only enhance the capabilities of industrial 3D printers but also cater to an environmentally conscious market, paving the way for greener manufacturing processes.

As we venture into the future, the evolution of 3D printing technology is set to transform industries in ways we never imagined. Beyond 2023, we can expect significant advancements in the materials used, with biocompatible and sustainable options becoming more mainstream. These innovations will not only enhance the capabilities of industrial 3D printers but also cater to an environmentally conscious market, paving the way for greener manufacturing processes.

Tips: When considering investing in industrial 3D printers, prioritize those that offer compatibility with emerging materials. Staying adaptable to new technologies will future-proof your production line and give you a competitive edge.

Additionally, the integration of AI and machine learning into 3D printing processes will enhance precision and efficiency. By leveraging data analytics, companies can optimize their printing techniques, significantly reducing waste and improving turnaround times. This shift toward automated solutions will allow manufacturers to produce complex components with unparalleled accuracy.

Tips: Keep an eye on the latest AI-driven 3D printing solutions, as they can streamline operations and significantly reduce your overall costs. Regularly training your team on these technologies will ensure your business remains at the forefront of industry innovation.