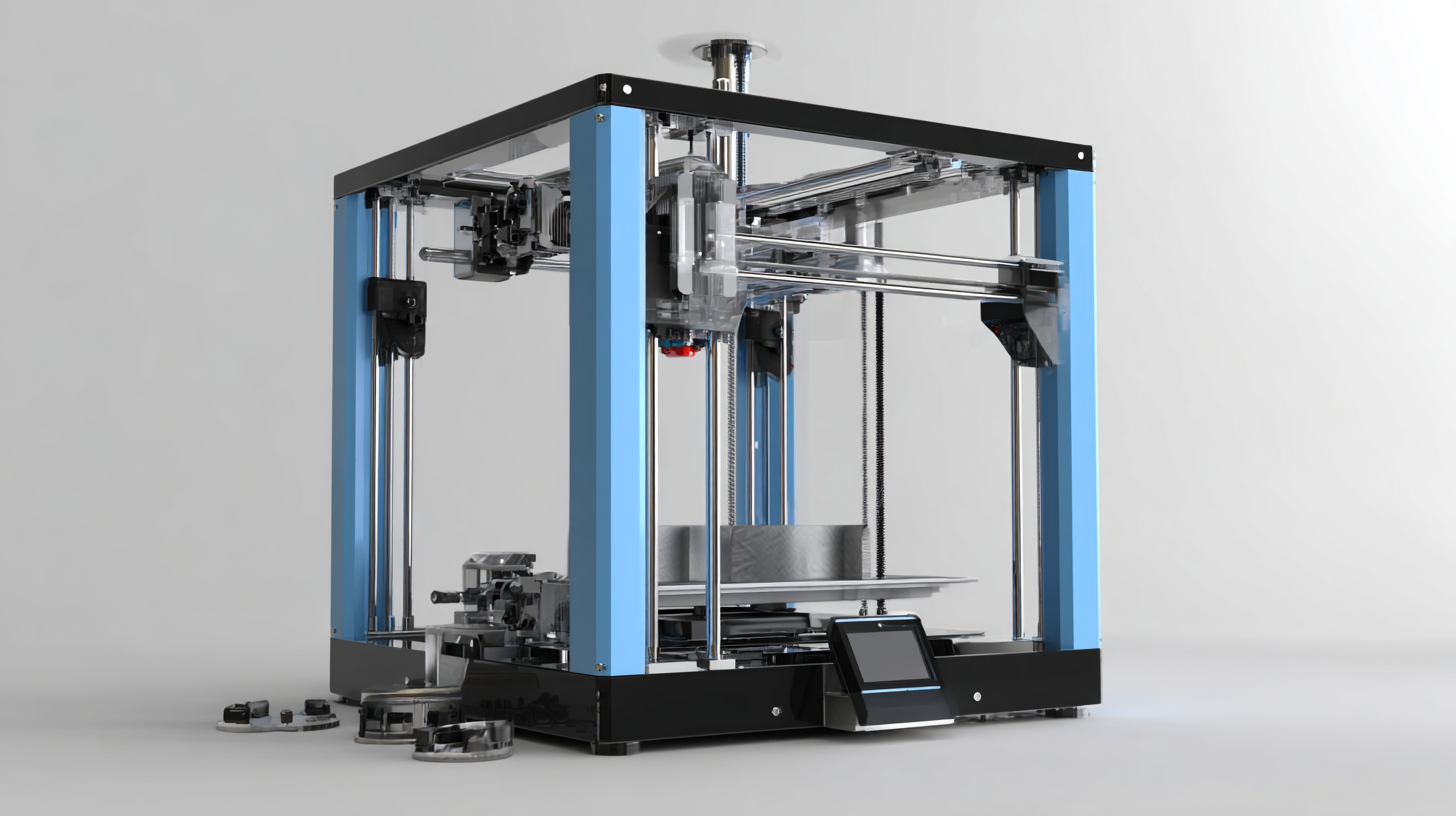

Innovative Solutions for Optimizing Your Best 3D Printing Machine Performance

The rapid advancement of technology has made 3D printing a pivotal component in various industries, from aerospace to healthcare. According to a report by MarketsandMarkets, the global 3D printing market is projected to reach USD 62.79 billion by 2026, growing at a CAGR of 23% from 2021. As businesses increasingly invest in high-quality 3D printing machines, optimizing their performance becomes crucial for enhancing productivity and maintaining a competitive edge. Finding reliable suppliers is key to this optimization process, as the right partnerships can lead to better materials, innovative technologies, and superior customer support.

In this blog, we will explore effective strategies for identifying top-tier suppliers that can help you maximize the potential of your 3D printing machine and streamline your production processes.

Maximizing Performance: Key Metrics for Assessing Your 3D Printing Machine Efficiency

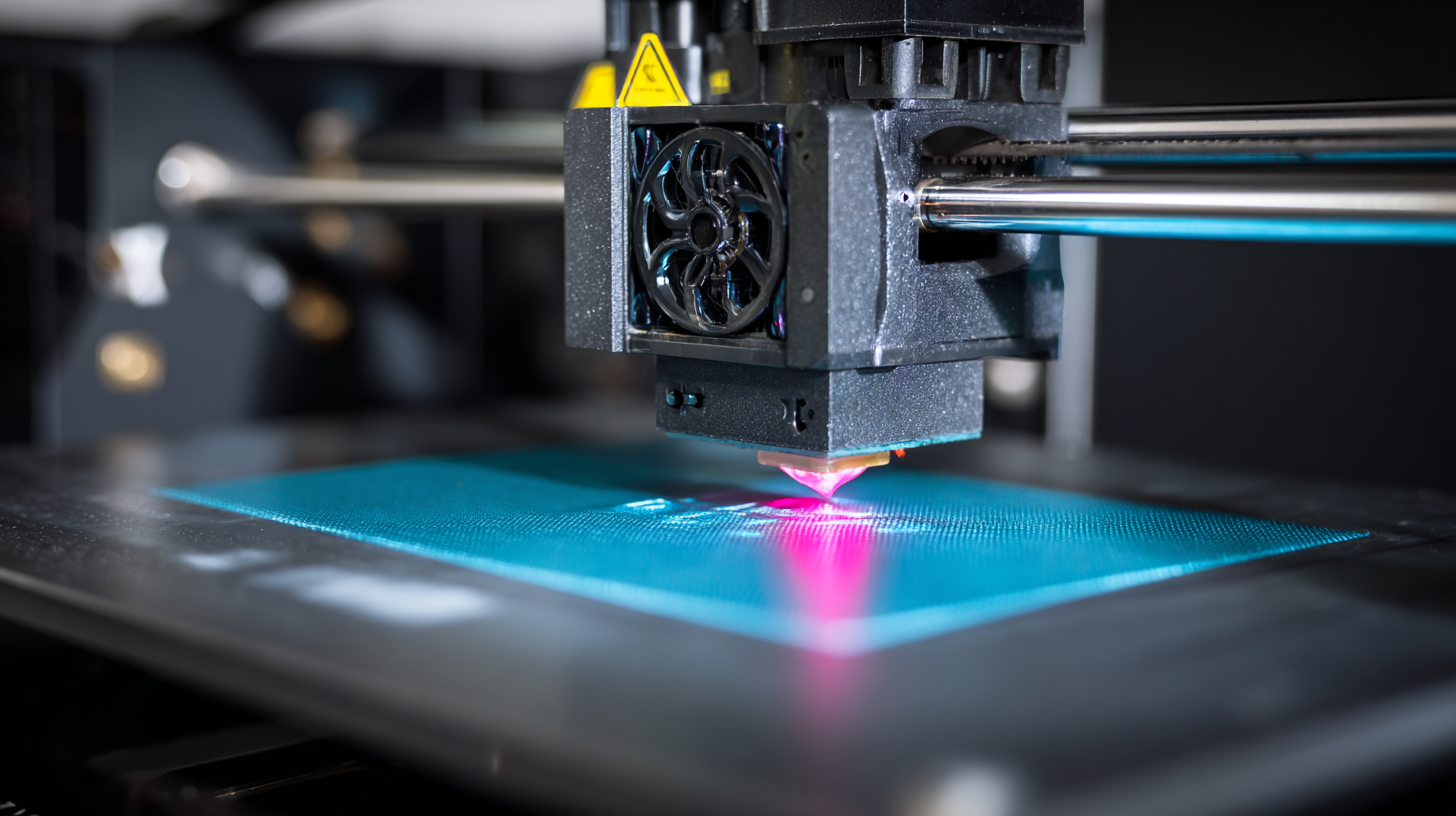

When it comes to optimizing the performance of your 3D printing machine, understanding key metrics is essential for assessing efficiency. One of the most significant metrics is layer adhesion, which directly impacts the strength and durability of printed objects. According to a study published by the American Society for Testing and Materials (ASTM), enhancing layer adhesion can reduce print failure rates by up to 40%. This improvement not only saves material costs but also accelerates production times, making it more viable for businesses to meet tight deadlines.

Another critical metric to monitor is print speed. Recent reports from the Wohlers Associates 2022 State of 3D Printing report indicate that advancements in nozzle technology have allowed for speeds to increase by 20-30% without compromising quality. Efficient speed management can lead to significant time savings, which is crucial in industries that rely on rapid prototyping or high-volume production. Furthermore, utilizing advanced slicing software can optimize print patterns and reduce unnecessary movements, further enhancing overall efficiency. By focusing on these key metrics, manufacturers can ensure they are maximizing the potential of their 3D printing systems.

Innovative Techniques for Enhancing Print Quality and Reducing Waste in 3D Printing

Innovative Techniques for Enhancing Print Quality and Reducing Waste in 3D Printing

The world of 3D printing is rapidly evolving, with innovative solutions emerging to enhance print quality while minimizing waste. One of the most exciting advancements is the development of printers that can operate without supports, dramatically reducing material waste and promoting sustainable production. Utilizing recycled polymer plastics and natural waste materials not only optimizes the printing process but also contributes to a greener manufacturing ecosystem.

Tips for optimizing 3D print quality include calibrating your printer regularly to ensure precise movements and accurate layer adhesion. Additionally, consider experimenting with various filament types that boast enhanced properties, such as improved strength or reduced warping. Implementing advanced software tools that focus on slicing and model preparation can further enhance print outcomes while decreasing errors that lead to wasted material.

Incorporating innovative materials, such as biocomposites, can also enhance your printing results. These materials are often more environmentally friendly and can improve the overall performance of your printed products. As the industry continues to explore the potential of smart farming and personalized nutrition, leveraging these advanced techniques will not only refine your 3D printing capabilities but also pave the way for a more sustainable future in manufacturing.

Cost-Benefit Analysis: Investing in Upgrades for Your 3D Printing Technology

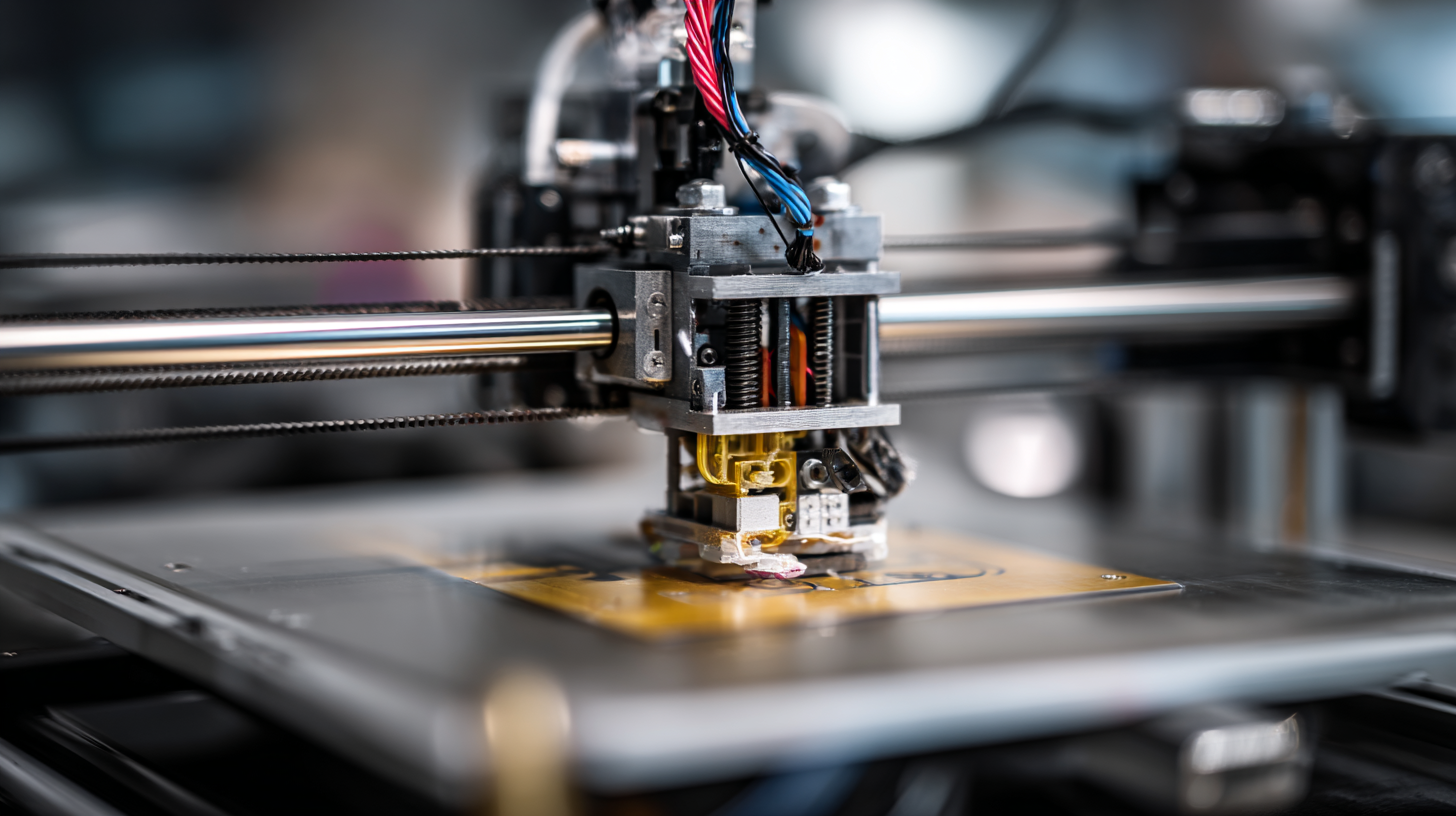

When considering an upgrade to your 3D printing technology, a thorough cost-benefit analysis is crucial. Investing in advanced components or features can significantly improve the performance and capabilities of your 3D printing machine. For instance, upgrading to a higher quality print head can enhance resolution and speed, reducing the time and materials needed for production. Evaluating the potential increase in output quality and efficiency against the initial expenditure allows you to make a more informed decision.

Additionally, incorporating enhanced software tools can optimize print settings and reduce material waste. Although the upfront costs may seem daunting, the long-term savings in time, material costs, and improved product quality can far outweigh these initial investments. By systematically assessing the return on investment of such upgrades, you can ensure that each enhancement contributes positively to your business's bottom line, ultimately positioning your 3D printing operations for growth and innovation.

Exploring Material Innovations: The Impact on Production Speed and Product Quality

In the rapidly evolving field of 3D printing, material innovations play a pivotal role in enhancing both production speed and product quality. Recent studies indicate that the adoption of advanced materials can increase 3D printing efficiency by up to 40%. For instance, the introduction of high-speed polymers has allowed manufacturers to reduce layer curing times significantly, thus accelerating the overall printing process. According to a report by SmarTech Analysis, industries leveraging innovative materials saw a 25% improvement in product quality, owing to enhanced mechanical properties and surface finish.

Moreover, the integration of new composite materials has transformed the landscape of additive manufacturing. Research by Wohlers Associates reveals that materials like carbon fiber-reinforced plastics not only improve strength-to-weight ratios but also enhance dimensional accuracy. This directly contributes to higher product reliability, which is crucial in critical applications such as aerospace and medical devices. As companies continue to explore and invest in material innovations, they will not only optimize their 3D printing workflows but also set new standards for product excellence in the market.

Real-World Case Studies: Success Stories of Optimized 3D Printing Processes in Manufacturing

In the realm of 3D printing, enhanced performance is a driving force behind successful manufacturing processes. Real-world case studies showcase how companies have transformed their operations through innovative optimization strategies. For instance, a leading automotive parts manufacturer faced challenges with production speed and material waste. By implementing advanced slicing algorithms and upgrading their printer's firmware, they managed to reduce print times by 30% while significantly cutting down on excess material. This not only streamlined their workflow but also reduced costs, proving that even minor adjustments can lead to substantial improvements.

Another compelling example can be found in the aerospace industry, where precision and reliability are paramount. A small startup specializing in aerospace components utilized a comprehensive approach by integrating predictive maintenance tools alongside their 3D printing technology. This proactive strategy allowed them to identify potential equipment failures before they occurred, minimizing downtime and ensuring consistent print quality. The combination of real-time monitoring and strategic material selection resulted in a 40% increase in production efficiency, underscoring the significance of data-driven decisions in 3D printing optimization.

Optimizing 3D Printing Machine Performance: Real-World Case Studies

This chart illustrates the performance improvements as a result of optimized 3D printing processes in manufacturing. The data represents the percentage increase in efficiency, quality, and material savings based on various case studies.