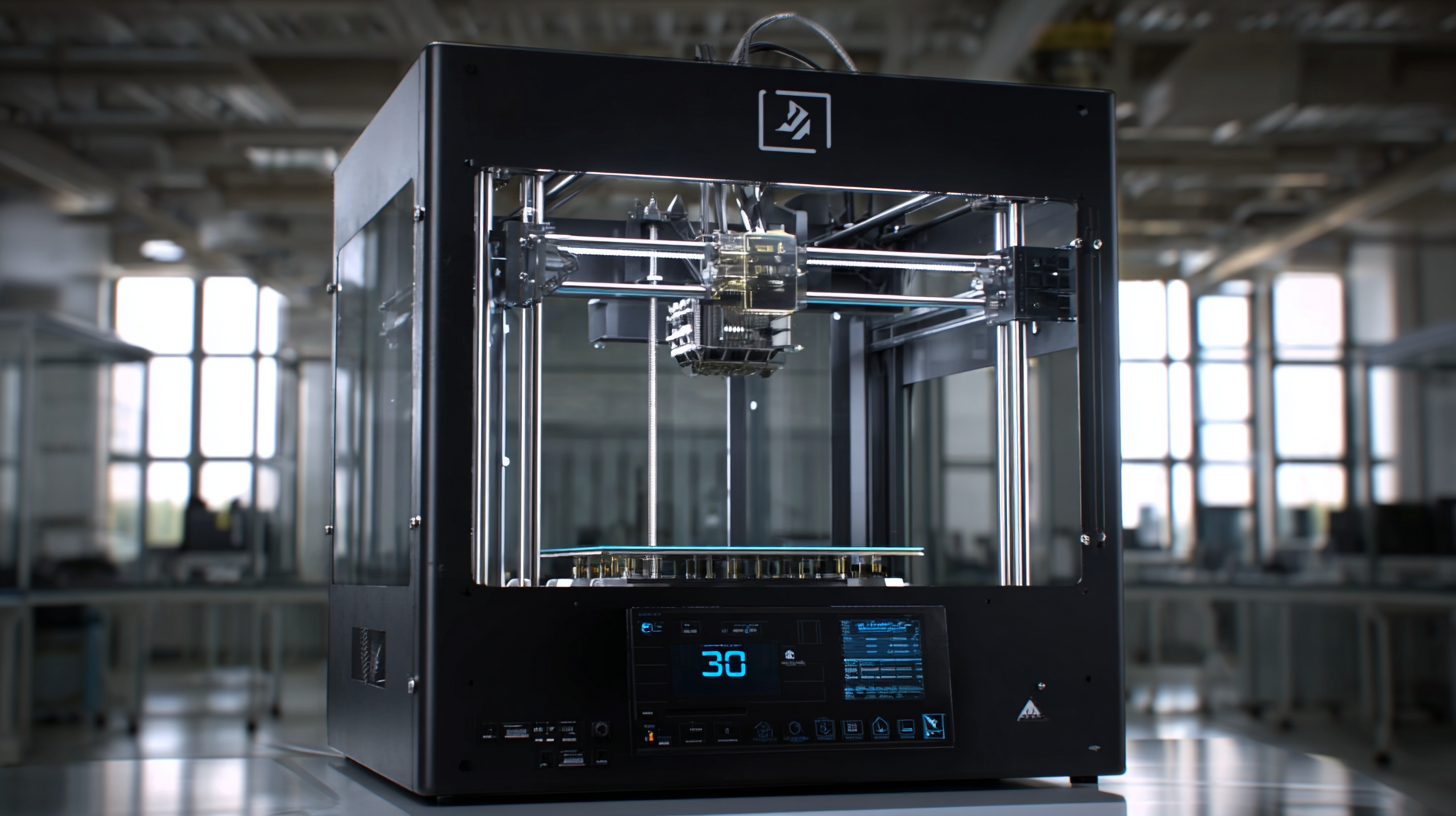

20 Key Features of the Best Industrial Metal 3D Printer for Global Buyers

As the demand for advanced manufacturing processes continues to rise, the industrial metal 3D printer has emerged as a

game-changing technology in various sectors, from aerospace to automotive.

According to a report by Wohlers Associates, the metal additive manufacturing market is projected to

grow to $6.9 billion by 2026, highlighting the increasing

adoption of this innovative technique among global buyers. The ability of industrial metal 3D printers to produce

lightweight yet robust components has revolutionized traditional

manufacturing methods, allowing for complex geometries and customized solutions that were previously

unattainable. In this blog, we will explore the 20 key features that define the best

industrial metal 3D printers, equipping prospective buyers with essential knowledge to make informed decisions in an

evolving landscape.

Key Advantages of Industrial Metal 3D Printing for Manufacturing Industries

Industrial metal 3D printing is revolutionizing manufacturing industries, offering significant advantages over traditional methods. According to a report by Wohlers Associates, the global metal 3D printing market is expected to grow from $5.5 billion in 2020 to over $16.2 billion by 2027. This growth signifies the increasing reliance on additive manufacturing for producing complex geometries and custom parts with reduced lead times. One of the key benefits is the reduction of material waste—traditional subtractive manufacturing processes often lead to excessive waste, whereas 3D printing allows for precise layer-by-layer construction, using only the necessary amount of material.

Moreover, industrial metal 3D printers enable the production of lightweight components, which is critical for industries such as aerospace and automotive. A study by McKinsey forecasts that additive manufacturing can reduce the weight of some parts by up to 30% without compromising their structural integrity. This not only enhances efficiency in production but also contributes to overall sustainability efforts within manufacturing. With the ability to rapidly prototype and iterate designs, companies are better equipped to innovate and respond to market demands, positioning themselves competitively in an ever-evolving landscape.

Essential Specifications to Consider When Choosing a 3D Printer

When selecting an industrial metal 3D printer, potential buyers should prioritize several essential specifications that can significantly impact production efficiency and output quality. One critical factor is the printer’s build volume, which affects the size of the objects that can be produced. According to a 2023 industry report by SmarTech Analysis, the average build volume for leading metal 3D printers is expanding, with most now offering dimensions of at least 300 x 300 x 300 mm. This increase allows for more complex geometries and larger components, which is vital for industries such as aerospace and automotive.

Another key specification is the type of metal materials supported by the printer. Factors like material compatibility and cost efficiency play significant roles in determining the overall production expenditure. A report from 3D Printing Industry indicates that stainless steel, titanium, and aluminum are among the most commonly used materials, with titanium reaching up to 7% of the market share in metal 3D printing due to its lightweight and high-strength properties. Furthermore, understanding the printer's layer thickness capabilities can also influence the final product's resolution. Devices that offer layer thicknesses as fine as 20 microns can provide enhanced detail and surface finish, distinguishing quality output in competitive markets.

Understanding Different Metal Printing Technologies and Their Benefits

Understanding different metal printing technologies is essential for global buyers looking to invest in the best industrial metal 3D printers. Two of the most prominent technologies in this field are Selective Laser Melting (SLM) and Electron Beam Melting (EBM). SLM uses a high-powered laser to fuse metal powder layers into solid structures, known for producing intricate and high-density components. On the other hand, EBM employs an electron beam in a vacuum to achieve similar results, allowing for faster printing speeds and the ability to work with reactive metals like titanium. According to a report by MarketsandMarkets, the metal 3D printing market is expected to reach $2.5 billion by 2025, highlighting the rapid technological advancements and increasing adoption across various industries.

When considering a metal 3D printer, buyers should focus on key features such as build size, material compatibility, and post-processing capabilities. A larger build size can accommodate more complex or bigger parts, while varied material compatibility ensures that the printer can handle different alloys and powder types, enhancing its versatility. Additionally, an efficient post-processing system can significantly reduce the time from production to final product, making the manufacturing process more streamlined.

Tips: Always evaluate the specific application needs of your production environment before selection, and don’t hesitate to request samples from manufacturers. Moreover, aligning printer capabilities with future scaling plans can foster sustained growth and innovation in your operations.

Factors Influencing the Cost of Industrial Metal 3D Printers

When considering the cost of industrial metal 3D printers, several key factors come into play. The initial investment typically varies based on the technology used, such as laser sintering or binder jetting. Advanced features, such as multi-material capabilities or enhanced precision, also influence the overall price. Additionally, the brand reputation and after-sales support can significantly affect costs, as established manufacturers often command a premium for their reliability and service offerings.

When considering the cost of industrial metal 3D printers, several key factors come into play. The initial investment typically varies based on the technology used, such as laser sintering or binder jetting. Advanced features, such as multi-material capabilities or enhanced precision, also influence the overall price. Additionally, the brand reputation and after-sales support can significantly affect costs, as established manufacturers often command a premium for their reliability and service offerings.

Tips for buyers include researching the total cost of ownership beyond the purchase price. This encompasses maintenance, material costs, and potential upgrades. Potential buyers should also consider the scalability of the printer; investing in a model that can grow with their production needs may save costs in the long run. Moreover, comparing various suppliers and their financing options can lead to better deals and help streamline the budgeting process. Understanding these factors can empower buyers to make informed decisions that align with their financial and operational needs.

Maintenance Tips to Ensure Longevity of Your 3D Printer

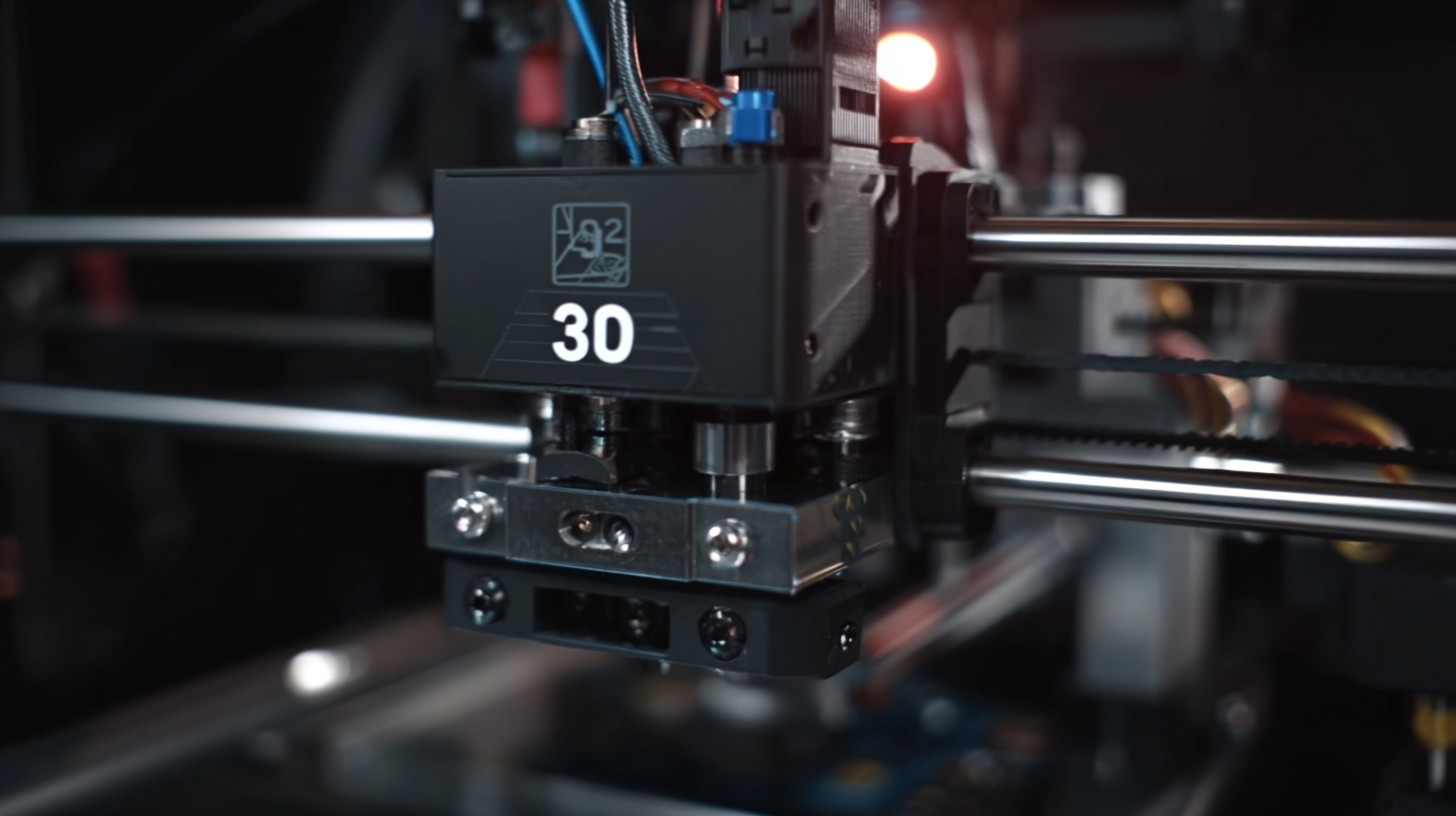

When it comes to investing in an industrial metal 3D printer, maintenance is key to ensuring its longevity and optimal performance. One important tip is to regularly inspect and clean the components. Accumulated dust and debris can lead to mechanical issues or poor print quality. Make it a routine to check the build plate, nozzle, and interior parts to keep everything running smoothly.

Another critical aspect of maintenance is monitoring the printer's environment. Keeping the machine in a controlled setting helps prevent temperature fluctuations and humidity levels that can negatively affect metal printing. Consider using a dedicated space with stable conditions to protect your investment. Additionally, always refer to the manufacturer's guidelines for specific maintenance schedules and recommended practices to follow.

Finally, don't overlook the importance of software updates. Keeping your 3D printer's firmware and slicing software up to date can significantly enhance its performance and capabilities. These updates often include bug fixes and new features that can lead to improved efficiency and print quality. By combining these maintenance tips, you can greatly extend the lifespan of your industrial metal 3D printer.

20 Key Features of the Best Industrial Metal 3D Printer for Global Buyers - Maintenance Tips to Ensure Longevity of Your 3D Printer

| Feature | Description | Maintenance Tip |

|---|---|---|

| High Resolution | Ability to produce detailed prints with precision. | Regularly clean the nozzle to prevent clogs. |

| Large Build Volume | Capable of printing large parts in a single piece. | Ensure the build platform is leveled before use. |

| Material Versatility | Compatible with various metal powders. | Store powders in a moisture-free environment. |

| User-Friendly Software | Intuitive interface for easy operation. | Keep software updated for performance improvements. |

| Thermal Management | Efficient temperature control during printing. | Regularly check heater cartridges for wear. |

| Automated Calibration | Self-calibration for correct setup. | Perform manual calibration periodically. |

| Safety Features | Includes sensors and alarms for safe operation. | Test safety systems regularly to ensure functionality. |

| Integrated Post-Processing | Built-in solutions for surface finishing. | Check alignment of post-processing tools. |

| Robust Build Quality | Durable construction for industrial settings. | Inspect frame and components regularly for integrity. |

| Customizable Settings | Allows user-defined parameters for different prints. | Experiment with settings for optimal results. |

| Remote Monitoring | Track printing progress from anywhere. | Ensure network connectivity is stable. |

| Energy Efficiency | Low power consumption during operation. | Schedule maintenance during off-peak hours. |

| Support for Multi-Material Printing | Ability to use different types of materials in a single print. | Configure material feeds carefully to avoid jams. |

| High Build Speed | Fast production rate without sacrificing quality. | Monitor print jobs to avoid overheating components. |

| Detailed User Manual | Comprehensive instructions for users to follow. | Refer to the manual for troubleshooting techniques. |

| Customer Support | Access to expert assistance and advice. | Utilize support resources for maintenance queries. |

| Scalability | Ability to increase production capacity. | Evaluate needs regularly to optimize efficiency. |

| Affordable Running Costs | Low cost of operation over time. | Monitor usage and material waste to reduce costs. |