10 Key Factors to Choose the Best 3D Printer for Metal: Insights from 2023 Industry Trends

As the landscape of manufacturing continues to evolve, the demand for advanced technologies like a 3D printer for metal has surged, marking a significant shift towards more efficient and innovative production methods. In 2023, industry trends reveal that choosing the right 3D printer for metal is not just about the machine’s capabilities, but also understanding key factors that influence performance, reliability, and cost-effectiveness.

As companies seek to enhance their operations and stay competitive, this blog will explore ten essential criteria that can guide buyers in selecting the best 3D printer for metal that fits their specific needs. By delving into advancements in materials, precision, software integration, and post-processing techniques, we aim to equip you with valuable insights to make informed decisions in this dynamic sector.

Understanding Different Types of Metal 3D Printing Technologies Available in 2023

In 2023, the landscape of metal 3D printing technologies continues to evolve, presenting diverse options for manufacturers. Key methods include Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Binder Jetting.

SLM, which employs high-power lasers to melt metal powder, is widely recognized for producing highly dense parts with excellent mechanical properties. According to a recent report from SmarTech Analysis, SLM accounts for over 45% of the metal 3D printing market share, highlighting its popularity and effectiveness in aerospace and medical applications.

SLM, which employs high-power lasers to melt metal powder, is widely recognized for producing highly dense parts with excellent mechanical properties. According to a recent report from SmarTech Analysis, SLM accounts for over 45% of the metal 3D printing market share, highlighting its popularity and effectiveness in aerospace and medical applications.

On the other hand, EBM leverages high-energy electron beams in a vacuum to fuse metal powder layers, offering superior thermal efficiencies and reducing residual stresses in the final product. While SLM leads in precision, EBM is gaining traction, particularly in industries seeking to reduce production times and costs. Meanwhile, Binder Jetting is emerging as a cost-effective method, enabling the production of complex geometries without the need for high-energy sources. Recent market data suggests that Binder Jetting technology is projected to grow by over 30% in the next few years, as it appeals to sectors looking for rapid prototyping and mass production capabilities.

Tip 1: When selecting a metal 3D printing technology, consider the specific material properties required for your application, as each technology interacts differently with various metals.

Tip 2: Keep an eye on emerging technologies in the industry, as new methods can offer enhanced capabilities or cost advantages that might suit your production needs better.

Essential Technical Specifications to Consider for Metal 3D Printers

When selecting the best 3D printer for metal fabrication, understanding the essential technical specifications is crucial. A report by Wohlers Associates in 2023 highlighted that the demand for metal 3D printing is expected to grow at a CAGR of 27% through the next five years. Key specifications to evaluate include layer thickness, build volume, and material compatibility. For instance, printers that offer finer layer resolutions can achieve more intricate designs, which is increasingly important in sectors like aerospace and automotive where precision is paramount.

When selecting the best 3D printer for metal fabrication, understanding the essential technical specifications is crucial. A report by Wohlers Associates in 2023 highlighted that the demand for metal 3D printing is expected to grow at a CAGR of 27% through the next five years. Key specifications to evaluate include layer thickness, build volume, and material compatibility. For instance, printers that offer finer layer resolutions can achieve more intricate designs, which is increasingly important in sectors like aerospace and automotive where precision is paramount.

Another important factor is the type of metal printing technology employed. The market report indicates that Powder Bed Fusion (PBF) technologies, such as Selective Laser Melting (SLM) and Electron Beam Melting (EBM), lead in market share, making them a popular choice for high-quality output. It's essential to check whether the printer supports various metal powders, as versatility can significantly enhance production capabilities.

Tip: Look for printers equipped with advanced software that can streamline the design-to-production workflow. Additionally, consider assessing the post-processing options of the printer, as they can drastically affect the turnaround time from conception to finished product.

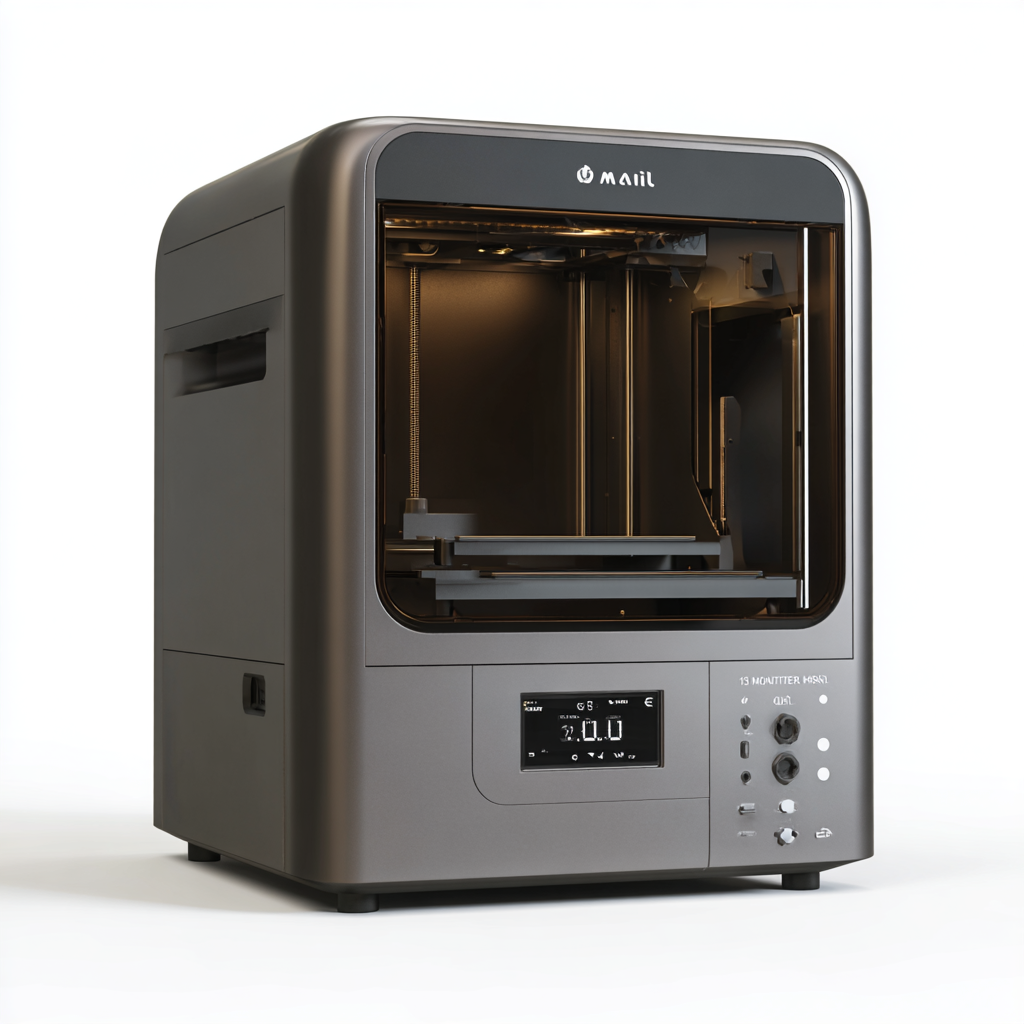

Evaluating Build Volume and Printer Size for Your Metal Printing Needs

When selecting a 3D printer for metal applications, evaluating the build volume and printer size is critical. According to a 2023 industry report from SmarTech Analysis, the demand for larger build volumes has surged, with a 40% increase in shipments of metal 3D printers featuring expanded build capacities. This trend highlights that businesses are striving for versatility and efficiency, aiming to minimize print failures and maximize the use of materials. A larger build volume enables the production of complex geometries and multiple parts in a single print run, which is essential for industries such as aerospace and automotive where production speed and reduced costs are paramount.

Furthermore, the footprint of a 3D printer can significantly impact the overall workspace in manufacturing environments. A 2023 study by MarketsandMarkets indicated that compact printers with advanced capabilities are gaining traction, with a projected increase in market share of 30% over the next five years. Smaller printers are often preferred for research and development facilities that require rapid prototyping without occupying excessive floor space. Therefore, considering both build volume and printer size not only defines the scope of what can be produced but also aligns with the operational dynamics of modern manufacturing.

Material Compatibility: Key Alloys and Filaments for Metal 3D Printing

When selecting the best 3D printer for metal, one of the most critical aspects is material compatibility. Understanding the key alloys and filaments available for metal 3D printing can significantly impact the quality and application of the finished product. Notable advancements in materials have emerged, including innovative aluminum compositions specifically developed for additive manufacturing, which enhance performance and ease of use. As the market trends indicate, the availability of affordable metal 3D printers has increased, making it feasible for businesses to invest in reliable machines without exceeding budget constraints.

Tips: When evaluating material compatibility, consider not only the types of metals you want to use, such as titanium or stainless steel, but also the specific requirements of your projects. Ensure the chosen printer supports the necessary alloys and is compatible with your desired print settings. Additionally, keep an eye on emerging materials—recent advancements in flexible filaments look to overcome challenges that have historically limited their functionality in automated environments.

Furthermore, attending industry events like RAPID + TCT can provide insights into the latest materials and technologies, as well as networking opportunities with experts and manufacturers. Staying updated with new releases can help you identify the best options for your specific 3D printing needs.

Precision and Resolution: Measuring Performance in Metal 3D Printing

When selecting the best 3D printer for metal, precision and resolution are critical factors that significantly impact the quality of the final product. A printer's ability to maintain tight tolerances can determine the effectiveness of complex designs and detailed components. Different metal 3D printing technologies, such as DMLS (Direct Metal Laser Sintering) and SLM (Selective Laser Melting), each offer unique resolution capabilities. It's essential to assess how these technologies align with your specific project needs to ensure optimal results.

One tip for evaluating a 3D printer's precision is to look at the layer height specifications. A lower layer height typically correlates with higher resolution, allowing for finer detail and smoother surfaces. Additionally, consider the build volume—large volumes can create more complex geometries but may require more precise machinery to maintain consistent quality throughout the entire build.

Another vital aspect is the printer's calibration process. Regular calibration ensures that the machine produces consistent results over time. Before purchasing, inquire about the manufacturer's calibration features or support. Implementing a routine calibration schedule can help maintain the printer's performance, ensuring that every layer is flawlessly printed and within the desired specifications. This approach will not only enhance the reliability of your metal 3D printing endeavors but also expand your creative potential.

10 Key Factors to Choose the Best 3D Printer for Metal: Insights from 2023 Industry Trends

| Factor | Importance Level | Performance Metric | Typical Range |

|---|---|---|---|

| Build Volume | High | Maximum part dimensions | 100 x 100 x 100 mm to 300 x 300 x 400 mm |

| Layer Thickness | High | Minimum achievable layer height | 20 µm to 100 µm |

| Material Compatibility | Medium | Number of supported materials | 5 to 15 materials |

| Print Speed | Medium | Speed at which prints are made | 10 cm/h to 30 cm/h |

| Post-processing Requirements | High | Need for additional finishing | Low to High |

| Software Integration | Medium | Ease of use and design software | Basic to Advanced compatibility |

| User Support | Medium | Availability of customer service | 24/7 to Business Hours |

| Cost of Operation | High | Ongoing material and maintenance costs | $100 to $2000/month |

| Precision | High | Dimensional accuracy | ±0.05 mm to ±0.1 mm |

| Resolution | High | Surface finish quality | Ra 0.4 to Ra 3.2 μm |