Top 10 High Volume 3D Printers for Efficient Large-Scale Production

In recent years, the demand for high volume 3D printers has surged, driven by advancements in technology and a growing need for efficient large-scale production across various industries. According to a report by Research and Markets, the global 3D printing market is expected to reach $41 billion by 2026, with significant contributions coming from the realm of high volume manufacturing. This emerging segment signifies a shift, enabling businesses to produce complex geometries at unprecedented speeds while reducing material waste.

High volume 3D printers play a pivotal role in transforming traditional manufacturing processes. They offer remarkable scalability and flexibility, allowing companies to respond swiftly to market demands. A study published in the Journal of Additive Manufacturing highlights that organizations utilizing these systems have reported production cost reductions of up to 50% compared to conventional methods. As industries such as automotive, aerospace, and healthcare increasingly adopt additive manufacturing technologies, the ability to produce large quantities rapidly and efficiently is becoming a competitive advantage. The following outline will delve into the top 10 high volume 3D printers, exploring their specifications, capabilities, and the unique benefits they bring to large-scale production environments.

Overview of High Volume 3D Printers in Large-Scale Production

High volume 3D printers are revolutionizing large-scale production across various industries by offering unparalleled efficiency and flexibility. Their ability to produce large quantities of parts swiftly not only reduces manufacturing lead times but also minimizes material waste.

With advancements in additive manufacturing technology, businesses can now take advantage of printers that feature larger build volumes, enhanced speed, and higher throughput, leading to a more streamlined production process that can meet demanding schedules.

One of the key benefits of high volume 3D printers is their versatility in producing complex geometries that are often challenging to achieve with traditional manufacturing methods. They are capable of using a wide range of materials, enabling manufacturers to tailor their products to specific requirements while maintaining strong mechanical properties.

Moreover, these printers facilitate rapid prototyping and iterative design processes, allowing companies to quickly pivot based on market demands and consumer feedback. By integrating high volume 3D printing into their operations, businesses can enhance productivity, reduce costs, and ultimately gain a competitive edge in their respective markets.

Key Features to Consider When Choosing 3D Printers for Efficiency

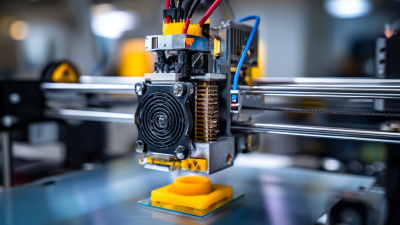

When selecting high-volume 3D printers for efficient large-scale production, several key features should be prioritized to ensure optimal performance. First and foremost, print speed and layer resolution are crucial metrics. A printer that can deliver faster print times while maintaining high precision will maximize productivity, allowing for quicker turnaround on projects. Additionally, the build volume of the printer is significant; larger machines can accommodate bigger parts or multiple smaller parts in a single print run, further enhancing efficiency in production workflows.

Another vital consideration is the type of materials the printer can use. Versatility in compatible materials allows manufacturers to choose the best filament for their specific applications, maximizing functionality and reducing the need for multiple machines. Another aspect to assess is the reliability and maintenance requirements of the printer. A machine that requires less frequent servicing and has readily available support can minimize downtime and keep production levels consistent. Lastly, energy efficiency should also be evaluated, as it can greatly impact operating costs, making sustainable production more feasible in the long run. By focusing on these essential features, companies can effectively enhance their large-scale 3D printing capabilities.

Top 10 High Volume 3D Printers: Specifications and Capabilities

The demand for high-volume 3D printing has surged in various industries, contributing to a notable evolution in manufacturing processes. According to a report by Additive Manufacturing Global Report 2022, the market for industrial 3D printing is projected to reach $20.9 billion by 2026, with a significant portion driven by large-scale production capabilities. Manufacturers are increasingly looking for 3D printers that combine speed and precision, which is essential for meeting the growing needs of sectors such as automotive, aerospace, and healthcare.

When evaluating specifications and capabilities, key factors such as build size, materials compatibility, and throughput rates become paramount. High-volume 3D printers typically offer larger build volumes – often exceeding 1 cubic meter – allowing for the production of bigger parts or multiple units in a single print. Additionally, advancements in material technology have enabled these printers to work with an extensive range of polymers, metals, and composites, enhancing their versatility. For instance, a recent study highlighted that the adoption of industrial grade polymers can lead to a 30% reduction in production costs while increasing part durability.

Moreover, capabilities such as dual-material printing and automated finishing processes are becoming standard features. These advancements not only accelerate the production cycle but also reduce labor costs and post-processing efforts. In fact, a study by SmarTech Analysis indicates that the productivity of high-volume 3D printers can be up to five times greater than that of traditional manufacturing methods. This level of efficiency positions high-volume 3D printing as a transformative force in modern manufacturing, paving the way for innovative product designs and rapid prototyping solutions.

Comparative Analysis of Performance and Cost-Effectiveness

When assessing high-volume 3D printers for large-scale production, performance and cost-effectiveness are critical factors that influence decision-making. Performance metrics typically include print speed, accuracy, and material compatibility, which are essential for meeting high demand in various industries. High-speed printers can significantly reduce production lead times, allowing businesses to rapidly respond to market needs. Meanwhile, precision ensures that the dimensions of the produced components adhere to required specifications, reducing the need for post-processing and additional costs. Moreover, the range of materials that a printer can handle can dictate its versatility in application, making it a vital consideration for companies aiming to diversify their product offerings.

Cost-effectiveness extends beyond the initial investment in equipment and encompasses operational costs such as maintenance, material expenses, and energy consumption. A comprehensive cost analysis over the printer's lifecycle can reveal potential savings, helping businesses make informed choices. Additionally, operational efficiency, which includes factors like ease of use, downtime, and training requirements, plays a significant role in overall productivity and should not be overlooked. By evaluating these aspects in conjunction with performance metrics, companies can identify 3D printing solutions that not only meet their production needs but also align with their budgetary constraints and long-term strategic goals.

Top 10 High Volume 3D Printers for Efficient Large-Scale Production

Applications and Industries Utilizing High Volume 3D Printing Technologies

High volume 3D printing technologies are transforming various industries by enabling efficient large-scale production. Sectors such as aerospace, automotive, and healthcare are increasingly adopting these advanced manufacturing methods to streamline their operations and reduce costs. According to a report by Wohlers Associates, the global 3D printing market is projected to reach $35.6 billion by 2024, highlighting the growing importance of these technologies in mass production scenarios.

For manufacturers, the ability to produce components rapidly without the limitations of traditional manufacturing processes opens up new avenues for innovation. Industries are leveraging high volume 3D printing for applications ranging from creating complex geometries in aerospace components to producing customized medical implants. Research from Gartner indicates that about 75% of organizations plan to use 3D printing for production at scale in the near future, emphasizing its role in industrial transformation.

Tip: When considering high volume 3D printing, it's essential to evaluate the specific requirements of your production process, including material selection and machine capabilities, to optimize efficiency and output quality.

Furthermore, integrating high volume 3D printing into supply chains can significantly lower lead times and enhance flexibility in product design. A study by Smithers Pira found that businesses utilizing 3D printing are able to reduce production times by up to 50%, which is crucial for staying competitive in today’s fast-paced market.

Tip: Engage in continuous materials research to keep up with advancements, as selecting the right material can lead to better performance and cost efficiency in your applications.

Related Posts

-

Addressing Common Issues with Enclosed 3D Printers: A Comprehensive Guide

-

What is a High End 3D Printer and How It Transforms Your Creations

-

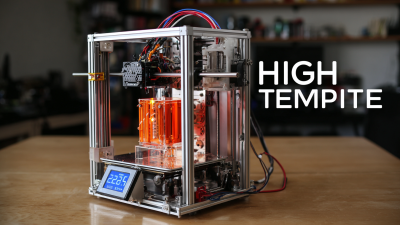

7 Essential Tips for Choosing the Best High Temperature 3D Printer

-

20 Essential Tips for Selecting the Best Professional 3D Printer

-

Top 5 Professional 3D Printers for High-Quality Prototyping and Design

-

2025 Top 10 Best 3D Printing Machines for Every Creative Professional