Exploring High Temperature 3D Printer Innovations at the 2025 China Import and Export Fair

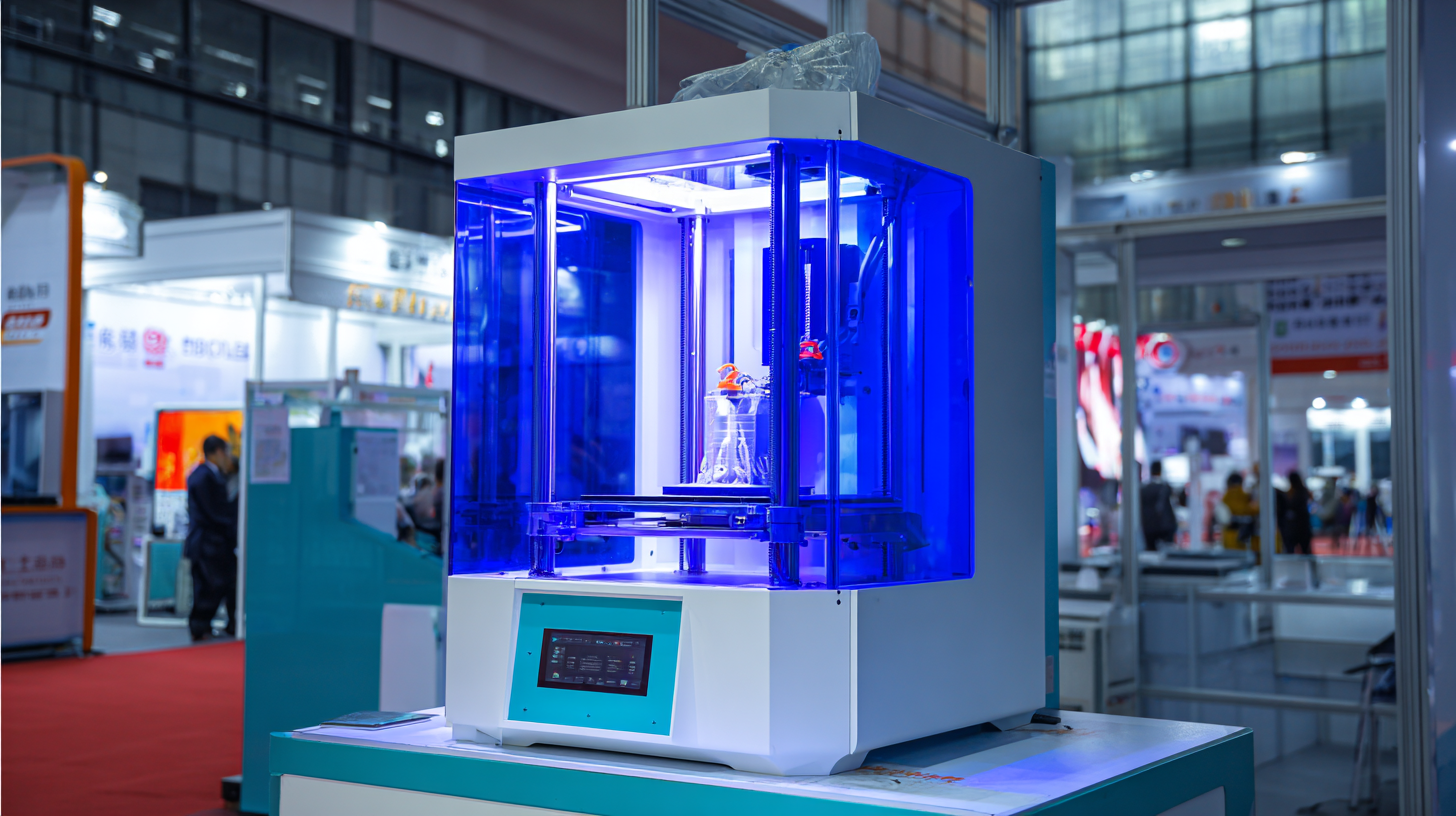

The 2025 China Import and Export Fair, the 138th edition of this prestigious event, serves as a pivotal platform for showcasing innovative technologies and products. This year, a notable focus will be on high temperature 3D printers, which have emerged as game-changers in various industries, including aerospace, automotive, and medical sectors. These advanced printing technologies are designed to process high-performance materials, enabling the creation of parts and prototypes that can withstand extreme conditions.

As manufacturers and designers continually seek ways to enhance efficiency and reduce costs, the introduction of these high temperature 3D printers promises to revolutionize traditional production methods. Attendees will have the opportunity to explore cutting-edge innovations, engage with industry leaders, and gain insights into the future of additive manufacturing, highlighting the significance of high temperature 3D printers in driving economic growth and technological advancement.

High-Temperature 3D Printing Technologies: A New Frontier for Manufacturing

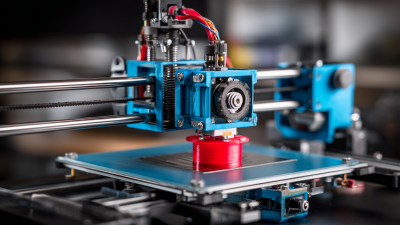

The advancement of high-temperature 3D printing technologies marks a significant evolution in the manufacturing sector, offering countless opportunities for innovation. These technologies enable the production of parts and components using advanced materials, such as high-performance thermoplastics and metals, which can withstand extreme conditions. This capability is crucial for industries ranging from aerospace to automotive, where durability and superior performance are paramount. The ability to create complex geometries with these materials not only enhances product functionality but also reduces waste and manufacturing time.

At the 2025 China Import and Export Fair, stakeholders will explore how these cutting-edge 3D printing technologies can transform traditional manufacturing processes. Exhibitors will showcase innovative designs that leverage high-temperature printing, demonstrating their potential to create lighter, stronger components that meet the rigorous demands of modern applications. As businesses seek to improve efficiency and reduce production costs, high-temperature 3D printing emerges as a viable solution, paving the way for a new frontier in manufacturing that emphasizes both sustainability and advanced performance.

Innovative Materials for High-Temperature 3D Printing Applications

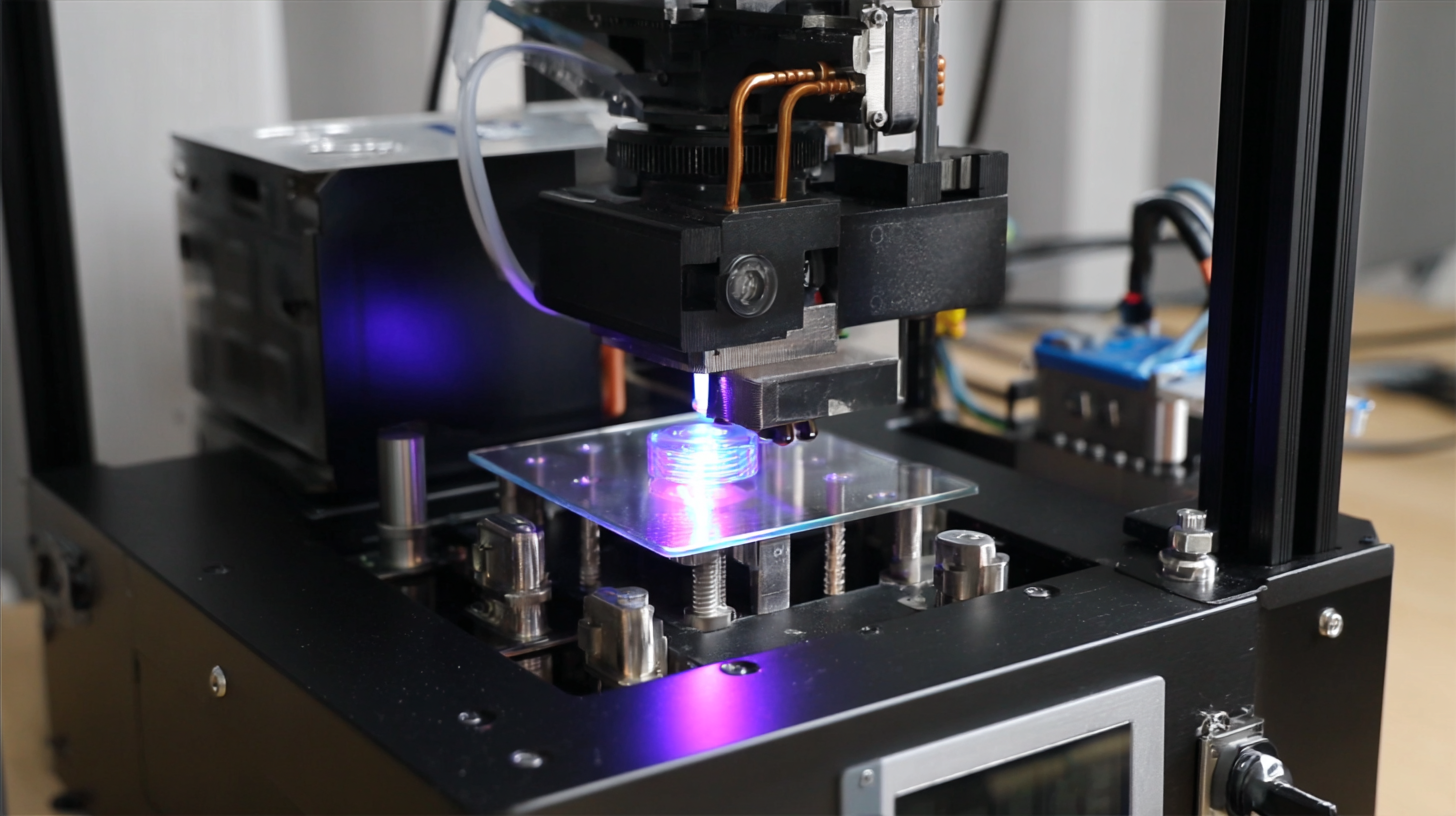

As the 2025 China Import and Export Fair approaches, innovations in high-temperature 3D printing materials are increasingly capturing attention. One exciting development is the introduction of specialized materials like iglide i230, designed to withstand extreme conditions and elevate performance in various high-temperature applications. According to industry reports, the market for high-temperature 3D printing materials is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, driven by advances in sectors such as aerospace and automotive manufacturing.

In addition to the advancements in materials, revolutionary processes have emerged. For instance, the fabrication of ceramic superconductors using a novel 3D printing method could pave the way for groundbreaking applications in electronics and energy systems. Interestingly, applying innovative material-forming techniques, such as synthetic polypeptides, promises to unlock potential in biomedical fields where precision and materials resilience are crucial.

Tip: When selecting high-temperature materials for 3D printing, consider factors such as thermal stability, tensile strength, and the specific application requirements to ensure optimal performance. Furthermore, as the landscape of high-temperature material capabilities expands, staying informed about recent advancements will help businesses leverage these innovations effectively.

Case Studies: Successful Implementation of High-Temperature 3D Printing

The 2025 China Import and Export Fair highlighted several case studies showcasing the successful implementation of high-temperature 3D printing, a technology gaining traction across various industries. According to a recent report by Mordor Intelligence, the global high-performance 3D printing materials market is expected to grow at a CAGR of over 20% from 2021 to 2026, driven by advancements in manufacturing and a growing need for customized solutions. Companies leveraging high-temperature 3D printers have realized significant efficiency improvements and material cost reductions, particularly in sectors such as aerospace and automotive.

One noteworthy example presented at the fair involved an aerospace manufacturer that utilized high-temperature 3D printing to produce lightweight, durable components. By adopting this innovative technology, the company achieved a 30% reduction in production time while simultaneously lowering the weight of aircraft parts by up to 20%. Furthermore, a case study from the automotive sector demonstrated how a leading manufacturer employed high-temperature 3D printing to streamline tooling processes, cutting lead times by nearly half and enhancing the capability for complex geometries that traditional manufacturing methods could not achieve. These examples underscore the transformative potential of high-temperature 3D printing in optimizing production workflows and enhancing product performance across industries.

Future Trends: The Evolution of High-Temperature 3D Printers in Industry

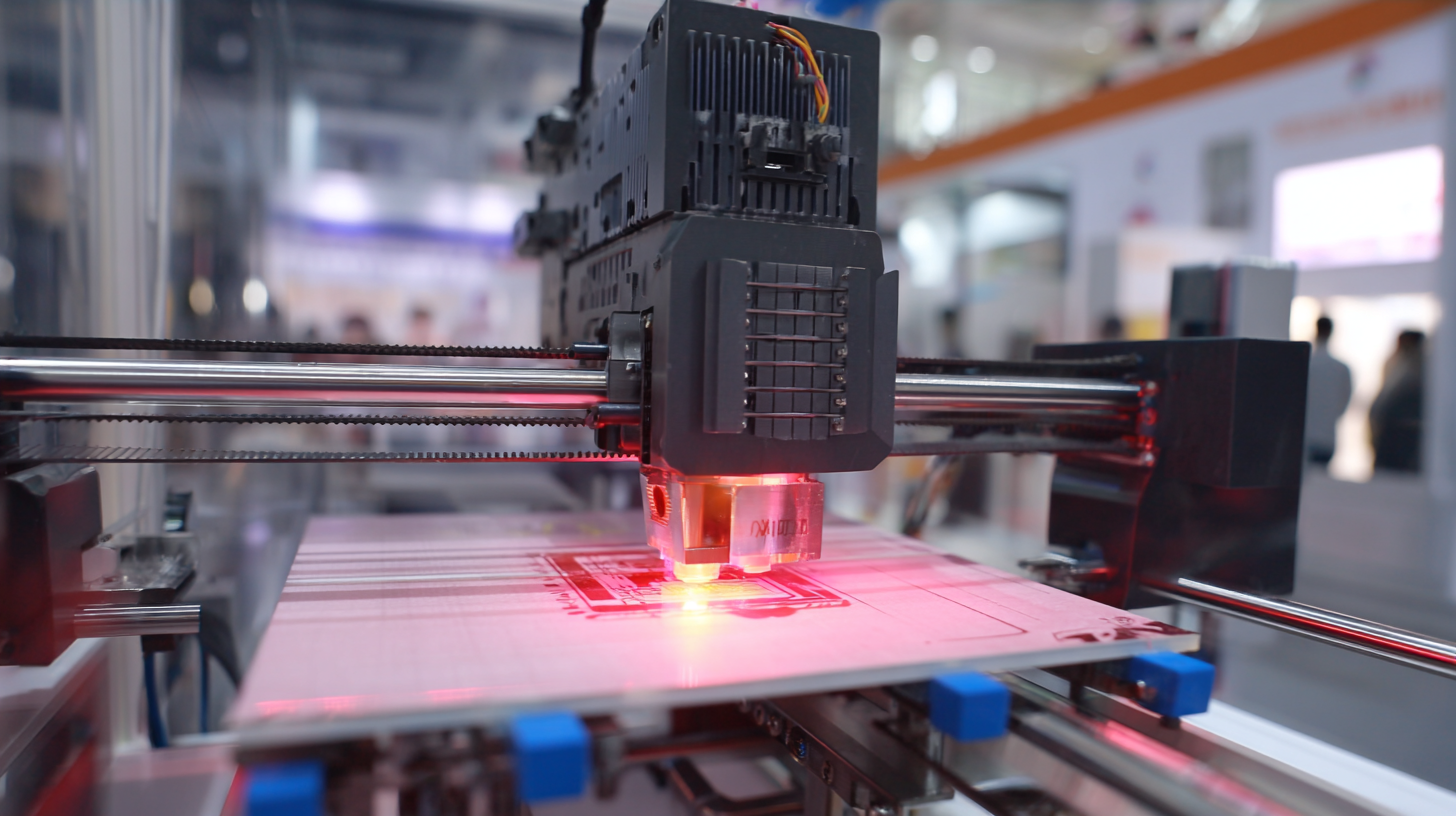

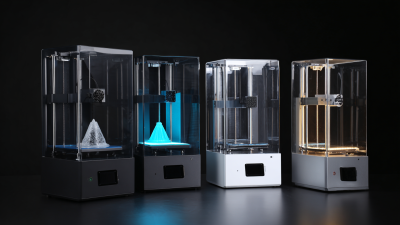

The evolution of high-temperature 3D printers is rapidly shaping the manufacturing landscape, reflecting a growing demand for advanced materials and capabilities. Recent innovations, such as all-in-one industrial FFF printers, illustrate how manufacturers are incorporating sophisticated technology to streamline production processes. These printers not only enhance the efficiency of printing complex geometries but also accommodate high-temperature materials, crucial for producing robust components for various industries.

Moreover, the trend towards larger format printers with high-speed and reliable production capabilities highlights a significant shift in the approach to additive manufacturing. The integration of automated systems allows for precision manufacturing, essential for meeting the rigorous standards of industrial applications. As companies anticipate a leap in 3D printing technology by 2025, the focus is decidedly on optimizing performance and expanding the potential for custom, cost-effective solutions that can satisfy the diverse needs of the marketplace. The advancements in network security features for 3D printers also signal a proactive approach to safeguarding intellectual property and operational integrity in an increasingly connected manufacturing environment.

Exploring Market Opportunities for High-Temperature 3D Printing Solutions

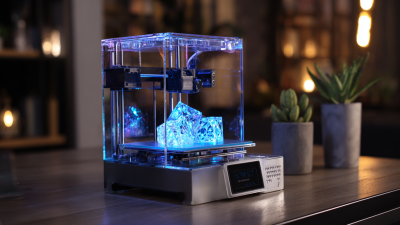

The advent of high-temperature 3D printing technology is reshaping industry standards, particularly in sectors that demand advanced materials capable of withstanding extreme conditions. According to a recent report from MarketsandMarkets, the global high-temperature 3D printing market is expected to reach $4.89 billion by 2026, growing at a CAGR of 25.4% from 2021. This growth is primarily driven by increasing applications in aerospace, automotive, and healthcare, where durable and heat-resistant components are crucial for performance and safety.

One of the most significant opportunities lies in the customization capabilities offered by high-temperature 3D printers. Businesses can produce components tailored to specific requirements, reducing waste and lead times. As industries continue to seek innovative solutions, the demand for materials like PEEK and ULTEM, known for their high thermal stability, is surging. The 2025 China Import and Export Fair presents a crucial platform for manufacturers and innovators to showcase these advanced materials and technologies.

Tips: When considering high-temperature 3D printing solutions, assess your specific industry needs and research materials that comply with your performance specifications. Engaging with suppliers at trade shows can also provide insights into the latest innovations and help you make informed decisions about integrating these technologies into your operations. Additionally, keep an eye on ongoing developments in additive manufacturing processes, as continuous advancements are expected to further enhance the capabilities of high-temperature 3D printers.

Related Posts

-

Crafting Excellence with the Best Mini 3D Printer from China for Global Markets

-

The Definitive Ultimate Guide to Finding the Best 3D Printing Machine for Your Business Needs

-

Ultimate Guide to Choosing the Best Enclosed 3D Printer for Your Business Needs

-

Quality Enclosed 3D Printers from China: Your Trusted Partner for Global Success

-

How Best Enclosed 3D Printers Will Transform the Market by 2025 with Key Insights and Strategies

-

Addressing Common Issues with Enclosed 3D Printers: A Comprehensive Guide