Envisioning the Future of 3D Printing: Why the Best Desktop Models Will Lead Innovation

As we stand on the brink of a new era in manufacturing and design, the role of desktop 3D printers has never been more pivotal. These compact yet powerful tools are not merely transforming individual creativity; they're redefining industry standards across various sectors. From rapid prototyping in engineering firms to personalized healthcare solutions, desktop 3D printers are at the forefront of innovation. This blog will explore compelling case studies that illustrate how these models are being utilized across different industries and will delve into the diverse types of desktop 3D printers available today. By understanding their capabilities and potential applications, we can better envision a future shaped by these remarkable technologies. Join us as we navigate the landscape of desktop 3D printing and its significant impact on tomorrow's innovations.

The Evolution of Desktop 3D Printing: From Hobbyist Tool to Essential Innovation Catalyst

The rise of desktop 3D printing has transformed from a niche hobbyist tool to a critical element of innovation across various industries. Initially embraced by enthusiasts and makers, these machines have advanced significantly in both capability and accessibility. Today, professionals in design, engineering, and education utilize desktop 3D printers to prototype ideas swiftly, test concepts, and streamline production processes, effectively reducing time and costs in product development.

Tip: When considering a desktop 3D printer, focus on the versatility of materials it can handle. A printer that accommodates a wide range of filaments will allow users to experiment with different textures, strengths, and finishes, enhancing creativity and functionality in projects.

As desktop 3D printing evolves, it fuels innovation by enabling new business models and manufacturing processes. Companies are leveraging this technology to customize products on demand, fostering a more personalized consumer experience. This capability not only meets the growing demand for unique solutions but also supports sustainable practices by minimizing waste through efficient production.

Tip: Keep an eye on software advancements that accompany hardware changes. A user-friendly interface can make 3D modeling more accessible, allowing designers of all skill levels to bring their ideas to life, thereby expanding the community and driving further innovation.

Key Features to Look for in High-Quality Desktop 3D Printers

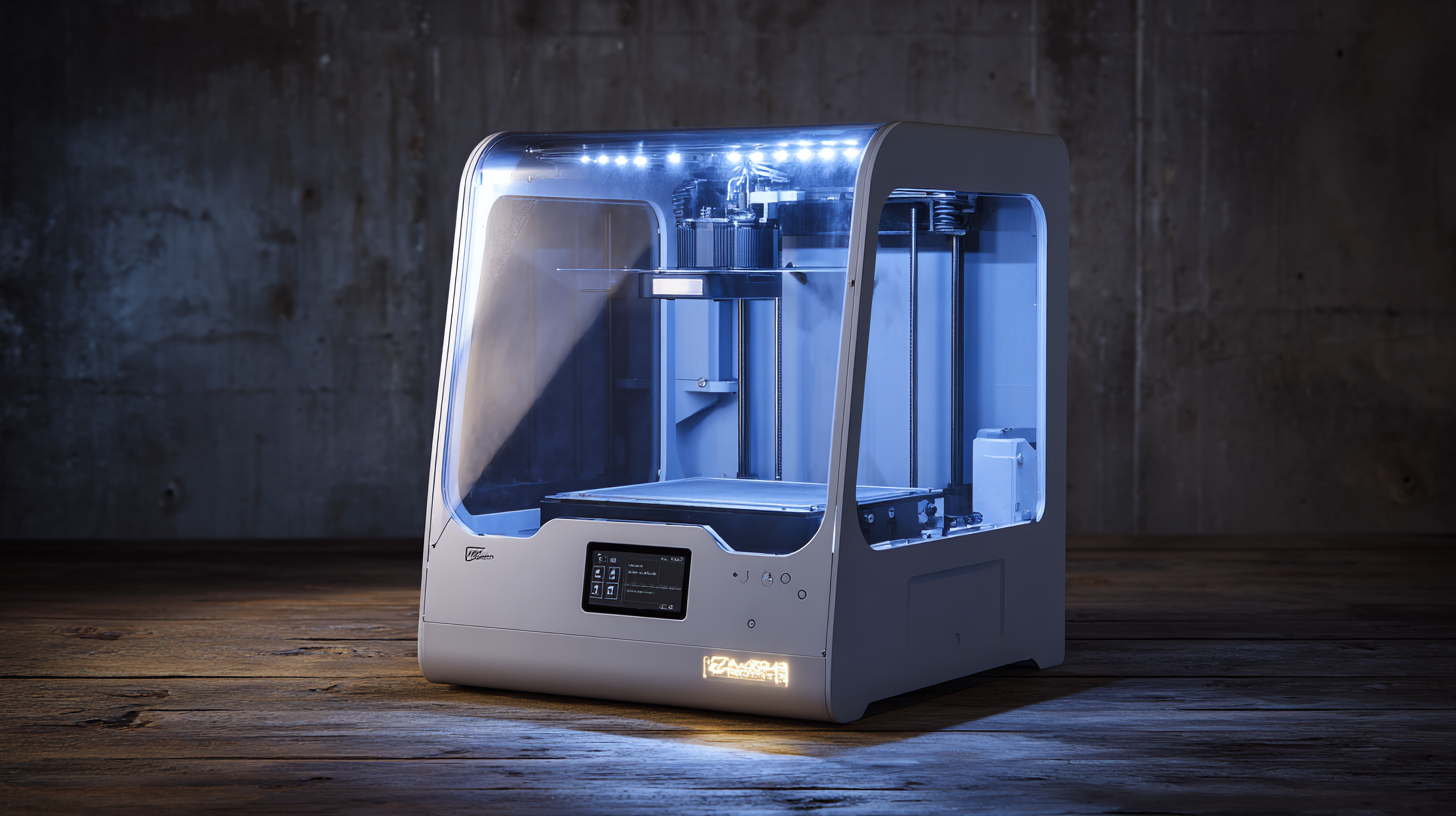

When considering high-quality desktop 3D printers, key features play a crucial role in driving innovation and advancing the technology. One of the most important aspects is print resolution. A printer with a higher resolution capabilities can create detailed and intricate designs, making it ideal for professionals and hobbyists alike. Look for models that offer adjustable settings, allowing users to balance speed and quality based on their specific needs.

Another vital feature to evaluate is build volume. A larger build volume enables users to create bigger objects or batch print smaller items simultaneously, enhancing productivity. Additionally, the ease of use is essential; printers equipped with user-friendly interfaces, automated calibration, and reliable software can significantly streamline the printing process. Compatibility with various materials, including a selection of advanced filaments, is equally important to foster creativity and innovation in projects. Choosing a desktop 3D printer with these key features can empower users to push the boundaries of what is possible in 3D printing technology.

Envisioning the Future of 3D Printing: Key Features in Desktop 3D Printers

Emerging Materials and Technologies Shaping the Future of 3D Printing

The landscape of 3D printing is rapidly evolving, driven by innovative materials and cutting-edge technologies. Over the next decade, we can expect significant advancements in the types of materials used, particularly with production-grade resins and structural composites that promise enhanced durability and recyclability. Recent research has pinpointed deformation mechanisms in 3D-printed materials, providing insights that could lead to the development of stronger and lighter components. This understanding is pivotal as industries strive for more resilient products that can withstand higher strains.

Moreover, new technologies are emerging in the realm of metal additive manufacturing, which is projected to witness substantial growth. The demand for metal printing hardware and materials is set to increase, further showcasing the potential of this manufacturing technique across various sectors. As these innovations take shape, 3D printing is expected to penetrate deeper into architecture and micro-nano device fabrication, paving the way for applications that were previously unimaginable. Such advancements not only highlight the versatility of 3D printing but also signal a forthcoming era of creativity and efficiency in manufacturing processes.

Real-World Applications: How Desktop 3D Printers Are Transforming Industries

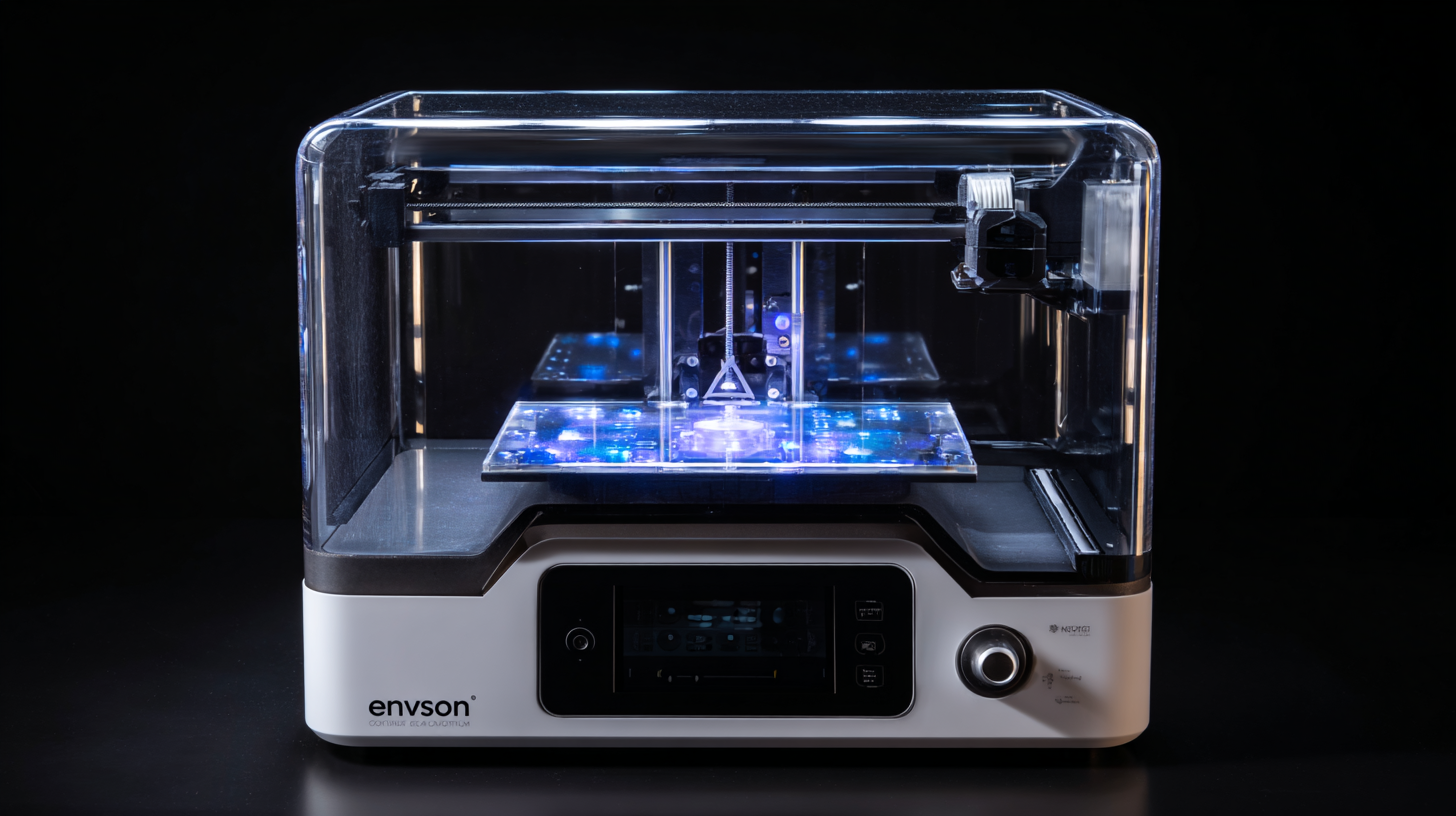

Desktop 3D printers are making waves across various industries, revolutionizing how products are designed and manufactured. In sectors such as healthcare, automotive, and education, these printers facilitate rapid prototyping, allowing companies to test ideas quickly without incurring heavy costs. For instance, hospitals can produce custom prosthetics tailored to individual patients, significantly improving rehabilitation outcomes.

Tip: When selecting a desktop 3D printer for industrial use, consider models that offer high precision and flexibility. Look for machines capable of handling various materials, from biodegradable plastics to metals, to expand your design possibilities and improve productivity.

Moreover, the educational landscape is being transformed as institutions integrate 3D printing into their curricula. Students are gaining hands-on experience in design and engineering, preparing them for future careers in tech and manufacturing. This engagement not only fuels creativity but also enhances problem-solving skills essential for the evolving job market.

Tip: Incorporate collaborative projects into your programs. Encouraging students to work together on 3D printing projects fosters teamwork and allows them to learn valuable lessons about project management and communication.

The Role of Community and Open Source in Advancing 3D Printing Innovation

The world of 3D printing is rapidly evolving, driven by the collaborative spirit found within communities and the principles of open source. These two elements are not just buzzwords; they are fundamental to pushing the boundaries of innovation in the field. By sharing designs, resources, and knowledge, makers around the globe are accelerating the development of new techniques and applications. This cooperative effort ensures that anyone, from hobbyists to industry professionals, can contribute to and benefit from advancements in 3D printing technology.

Tip: Get involved in local maker spaces or online forums to connect with fellow enthusiasts. These platforms allow you to exchange ideas, learn from others’ experiences, and even collaborate on projects that can lead to unexpected innovations.

Moreover, open source platforms provide access to a wealth of information and designs that are crucial for experimentation and growth. By leveraging freely available resources, users can modify and improve existing models, spurring creativity and practical problem-solving. This democratization of technology means that innovation is no longer limited to large corporations—it thrives within communities passionate about 3D printing.

Tip: Experiment with open-source design software to create your own unique models. This not only enhances your skills but also contributes to the collective knowledge pool that benefits the entire 3D printing ecosystem.