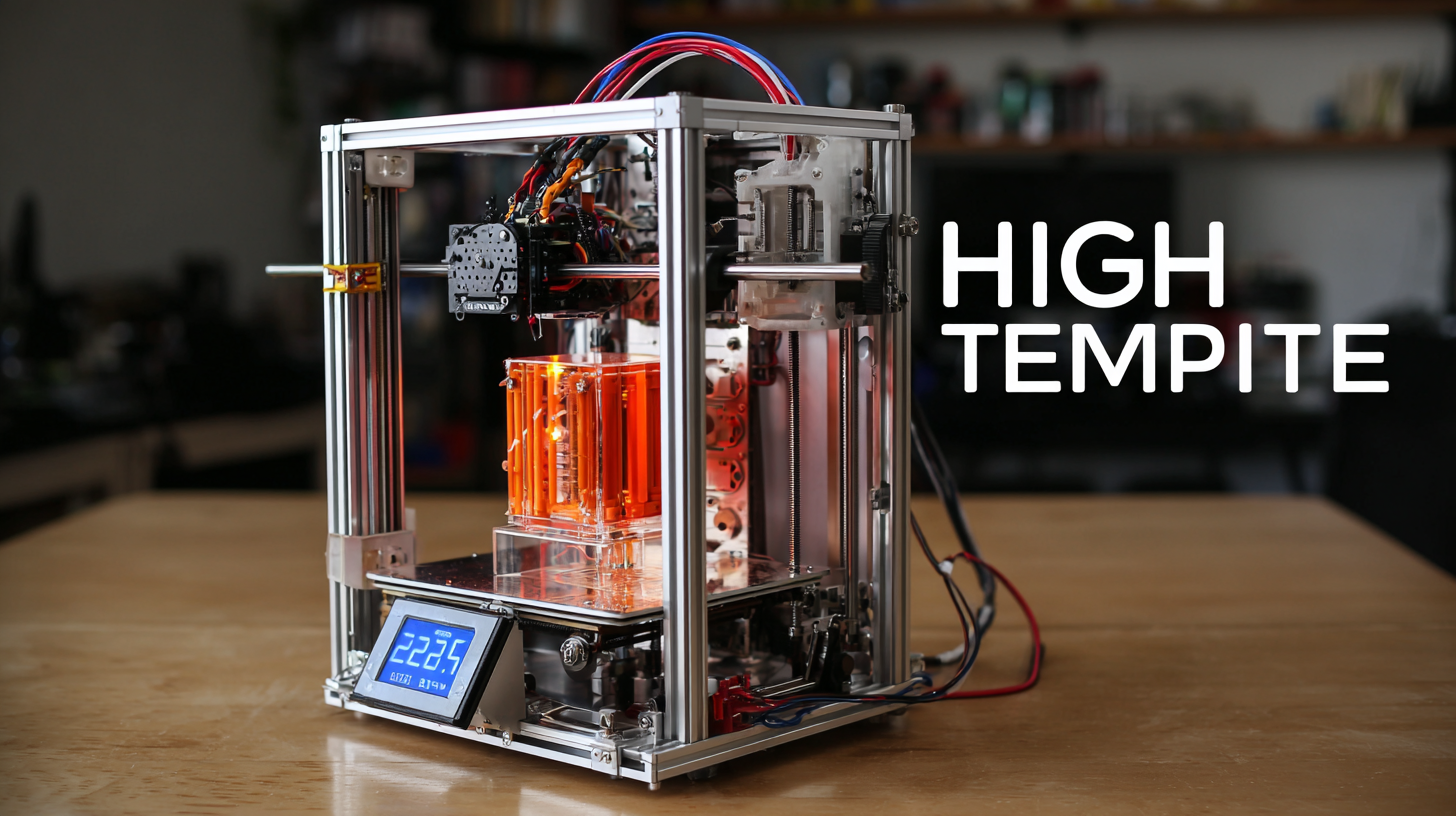

7 Essential Tips for Choosing the Best High Temperature 3D Printer

When it comes to the world of 3D printing, selecting the right equipment can make all the difference, especially for those dealing with high-temperature materials. A high temperature 3D printer is essential for professionals and hobbyists alike who aim to create durable, heat-resistant components that can withstand extreme conditions. However, with numerous options flooding the market, it can be overwhelming to determine which printer is the best fit for your needs. In this blog, we will explore seven essential tips to help you navigate the selection process. By considering factors such as material compatibility, build volume, and reliability, you can ensure that you choose a high temperature 3D printer that meets your demands. Join us as we delve into the intricacies of this technology and discover how to make an informed decision that aligns with your production goals.

Understanding the Importance of High-Temperature 3D Printing in Advanced Manufacturing

High-temperature 3D printing plays a crucial role in advanced manufacturing, especially in industries that demand high-performance materials and components. As additive manufacturing evolves, the importance of utilizing high-temperature 3D printers becomes ever more evident. These specialized printers enable the fabrication of parts that can withstand extreme environments, thereby fulfilling stringent requirements in aerospace, automotive, and medical applications. The ability to print with advanced materials, such as high-performance polymers and metal alloys, opens new avenues for innovation, allowing manufacturers to create lightweight and durable structures that traditional manufacturing processes cannot achieve.

Recent developments in the field showcase the transformative potential of high-temperature 3D printing. For instance, the aerospace industry is projected to experience significant growth, driven by the need for additive manufacturing to reduce waste and improve efficiency. By optimizing printing parameters and employing advanced materials, manufacturers can enhance the mechanical properties of their components, making them suitable for even the most demanding applications. The strategic shifts in manufacturing technologies highlight the increasing reliance on 3D printing as a means to drive progress in logistics and production, ultimately leading to more resilient and integrated supply chains.

Key Materials for High-Temperature 3D Printing: A Comparative Analysis of Options Available

When selecting the best high-temperature 3D printer, one of the most crucial factors is the materials you intend to use. High-temperature 3D printing opens up avenues for advanced materials that can withstand extreme conditions. Key options include PEEK, Ultem, and Nylon 12, each boasting unique properties that cater to different industrial needs.

PEEK, known for its excellent mechanical strength and chemical resistance, is ideal for aerospace and automotive applications where performance is paramount. On the other hand, Ultem provides high thermal stability and is often used in electronic components and medical devices.

In addition to these, Nylon 12 is another compelling choice due to its flexibility and durable nature. It is particularly useful in applications requiring complex geometries and resilience against impact. When comparing these materials, consider factors such as processing temperature, ease of printing, and the specific mechanical properties needed for your project. Understanding these characteristics will equip you to make an informed decision, ensuring that you choose a high-temperature 3D printer capable of utilizing the best materials for your applications.

Evaluating Temperature Range and Performance for Different 3D Printing Applications

When selecting a high-temperature 3D printer, evaluating the temperature range is crucial, as it directly impacts the types of materials you can effectively print. Typical thermoplastics like PLA and ABS may only require moderate temperatures, but if you're aiming to work with high-performance materials such as PEEK or PAEK, your printer should support temperatures exceeding 300°C. This capability opens the door to numerous industrial applications, from aerospace to automotive components, where durability and heat resistance are paramount.

Performance also plays a significant role in choosing the right printer for your needs. Look for features such as consistent extrusion rates, print speed, and layer adhesion at elevated temperatures. A printer designed with a high-quality hotend, appropriate heating elements, and an insulated build chamber can greatly enhance print quality and reduce warping or failure. Additionally, consider the cooling system's effectiveness, as managing the transition between layers is vital for achieving strong and precise prints in high-temperature materials. By carefully assessing these factors, you can ensure your 3D printing projects meet their demanding requirements.

Cost-Benefit Analysis: Investing in High-Temperature 3D Printers for Long-Term Gains

Investing in high-temperature 3D printers can bring long-term benefits that far outweigh the initial costs. As industries increasingly seek to enhance their production capabilities, the 3D printing market is projected to generate significant revenue, with estimates indicating a growth rate of 14.7% CAGR, leading to a market valuation of USD 6.9 billion by 2032. This demonstrates a robust demand for advanced manufacturing technologies, particularly in sectors where high-performance materials are critical for product durability and efficiency.

Furthermore, as companies commit to achieving net-zero emissions by 2050, the role of 3D printing in sustainable manufacturing cannot be overstated. By enabling more efficient production processes and reducing material waste, high-temperature 3D printers can help businesses adapt to the evolving climate regulations and consumer preferences for eco-friendly products. This aligns with the industry's shift towards more innovative solutions and could potentially lead to significant cost savings in the long run, making high-temperature 3D printers not just a technological investment but also a strategic move for companies aiming to thrive in a rapidly changing market landscape.

Market Trends and Future Projections for High-Temperature 3D Printing Technologies in China

The landscape of high-temperature 3D printing technologies in China is evolving rapidly, driven by a surge in demand across various industries such as aerospace, automotive, and healthcare. As manufacturers seek materials that can withstand extreme conditions, the technology is witnessing significant advancements. Recent trends indicate a growing investment in R&D aimed at improving the capabilities of high-performance filaments and printers that can operate at increased temperatures, enhancing material properties, and broadening application ranges.

Furthermore, the Chinese market is seeing a shift towards the adoption of high-temperature 3D printers among small and medium-sized enterprises (SMEs). These businesses are beginning to recognize the potential of high-temperature printing not just for prototyping, but for producing end-use parts that require durability and precision. With this growth, several local companies are emerging as leaders in the field, promoting innovative solutions that address specific industry needs. As these trends continue, the future of high-temperature 3D printing in China looks promising, poised to play a crucial role in the global manufacturing landscape.

7 Essential Tips for Choosing the Best High Temperature 3D Printer

| Tip | Description | Current Market Trend | Future Projections (2025) |

|---|---|---|---|

| 1. Material Compatibility | Choose printers that support a variety of high-temp materials. | Increasing demand for specialty filaments. | Projected 40% increase in multi-material printers. |

| 2. Temperature Range | Select printers that can reach high processing temperatures. | Emerging technologies allowing higher processing temperatures. | Expected advancements in material performance. |

| 3. Build Volume | Consider the size of objects you plan to print. | Growth in demand for larger build volumes. | Increase in machines capable of larger dimensions by 50%. |

| 4. Precision and Resolution | Assess print accuracy and layer resolution. | Higher precision printing gaining traction in industrial sectors. | Possibility of ultra-high-resolution printers emerging. |

| 5. Cost of Ownership | Evaluate long-term operational costs including materials and maintenance. | Cost reduction in high-temp materials expected. | Overall decrease in costs by approximately 30%. |

| 6. Customer Support and Community | Consider the availability of support resources and community feedback. | Growing forums and networks for 3D printing communities. | Improvement in collaborative support platforms expected. |

| 7. Reviews and Case Studies | Look for practical case studies for real-world applications. | Rising popularity of documented user experiences. | Increase in accessibility to user-generated content. |