Top 10 Enclosed 3D Printers for Safe and High Quality Printing

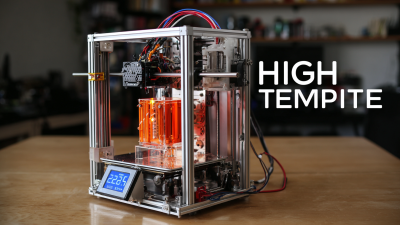

In recent years, the popularity of 3D printing has skyrocketed, revolutionizing various industries, from manufacturing to education. Among the numerous types of 3D printers available, the enclosed 3D printer has emerged as a favored choice for both amateurs and professionals alike. These printers, designed with an enclosed build chamber, offer enhanced safety and temperature control, making them particularly suitable for printing high-quality prototypes and intricate designs.

The enclosed design helps to maintain a consistent temperature during the printing process, reducing the risk of warping and improving the final product's quality. Furthermore, the enclosed environment provides a safer workspace, especially when working with materials that emit fumes or require specific handling. Whether you are a hobbyist exploring new creative possibilities or a professional seeking reliable industrial-grade machines, an enclosed 3D printer can significantly enhance your printing experience.

In this article, we will explore the top 10 enclosed 3D printers that stand out for their exceptional safety features and print quality. Whether you are looking to invest in your first 3D printer or upgrade your existing model, our comprehensive analysis will guide you to make an informed decision that meets your unique needs and goals in 3D printing.

Benefits of Using Enclosed 3D Printers for Safe Printing

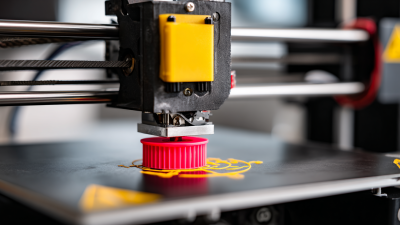

Enclosed 3D printers provide a range of benefits that enhance both safety and print quality, making them a popular choice among hobbyists and professionals alike. One of the primary advantages of an enclosed design is the ability to maintain a stable temperature throughout the printing process. This temperature control minimizes warping and ensures that filament adheres properly to the build plate, resulting in smoother and more precise prints. Furthermore, an enclosed environment significantly reduces the emissions of harmful particles and volatile organic compounds (VOCs) during printing, creating a safer workspace, especially in home and educational settings.

When using enclosed 3D printers, it's essential to implement some tips to maximize their benefits. Firstly, ensure that the printer's ventilation is adequate; while encapsulation helps maintain temperature, proper airflow is vital to dissipate any harmful emissions. Additionally, users should regularly check the seals and doors of the enclosure to prevent heat loss and maintain efficiency. Finally, utilizing high-quality filament specifically designed for enclosed printing can improve results, as these materials are often engineered to withstand the elevated temperatures within an enclosed chamber.

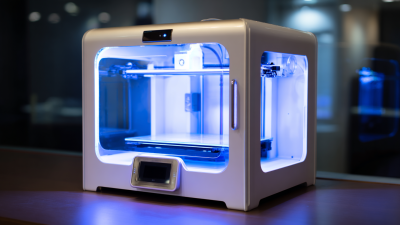

The enclosed design also adds an extra layer of safety, as it reduces the risk of accidental contact with moving parts and hot components. Users can feel more secure knowing that children and pets are less likely to reach the printer during operation. Overall, the combination of improved print quality and enhanced safety features makes enclosed 3D printers a reliable choice for anyone looking to elevate their 3D printing experience.

Key Features to Look for in Enclosed 3D Printers

When selecting an enclosed 3D printer, several key features should be prioritized to ensure both safety and quality in printing. One of the most critical aspects is temperature control. Enclosed systems minimize temperature fluctuations, reducing the risk of warping in thermoplastic materials, as reported in a 2023 study by the International Journal of Advanced Manufacturing Technology, which found that temperature-controlled environments can enhance print quality by up to 30%. It is essential to choose printers with effective heating systems and insulation to maintain a consistent ambient temperature throughout the print process.

Another significant feature to consider is the filtration system. Many enclosed 3D printers are equipped with HEPA or activated carbon filters that mitigate emissions from common printing materials like ABS and PLA. According to data from the Occupational Safety and Health Administration (OSHA), exposure to volatile organic compounds (VOCs) can have adverse health effects, emphasizing the importance of air quality in printing environments. A high-quality filtration system can significantly reduce VOC emissions, ensuring a safer workspace, especially in home or educational settings. Additionally, features like enclosed build chambers not only provide safety but also contribute to reducing noise levels during operation, making for a more pleasant user experience.

Lastly, user-friendly interfaces and software compatibility are vital for ease of use, particularly for those new to 3D printing. Printers that offer intuitive controls and are compatible with widely used slicing software lead to higher success rates in print jobs, as indicated by a 2022 survey conducted by the 3D Printing Industry which showed that 70% of users preferred printers with straightforward software integration. Ultimately, investing in an enclosed 3D printer with these key features will greatly enhance both safety and quality, making it a worthwhile consideration for any user.

Top 10 Enclosed 3D Printers for Safe and High Quality Printing

| Model | Build Volume (mm) | Max Temperature (°C) | Layer Resolution (μm) | Filament Compatibility | Enclosure Features |

|---|---|---|---|---|---|

| Model A | 300 x 300 x 400 | 260 | 50 | PLA, ABS, PETG | Heated bed, LED lighting |

| Model B | 250 x 250 x 300 | 250 | 75 | PLA, TPU | Fully enclosed, tempered glass door |

| Model C | 400 x 400 x 500 | 280 | 30 | PLA, ABS, ASA | Isolated chamber, HEPA filter |

| Model D | 300 x 300 x 300 | 260 | 20 | PLA, Nylon | Dual filtration system, WiFi connectivity |

| Model E | 350 x 350 x 400 | 250 | 100 | PETG, PLA | Smart humidity control, visualizer |

| Model F | 300 x 300 x 600 | 280 | 40 | PLA, ABS | Full enclosure with auto door |

| Model G | 250 x 250 x 250 | 245 | 50 | PLA, TPU, PETG | Easy access doors, air ventilation |

| Model H | 300 x 300 x 400 | 260 | 30 | PLA, ABS, Nylon | High temperature resistance, motherboard cooling |

| Model I | 350 x 350 x 400 | 240 | 50 | PLA, PETG, TPU | Noise reduction enclosure, touchscreen interface |

| Model J | 400 x 400 x 600 | 280 | 20 | ABS, ASA | Smart sensors, built-in camera |

Top 10 Enclosed 3D Printers: Overview and Specifications

Enclosed 3D printers have gained popularity due to their ability to provide a controlled environment, which is essential for achieving high-quality prints. These printers are designed to minimize external factors such as temperature fluctuations and drafts, ensuring consistent printing results. The enclosed space also facilitates safer operations by shielding moving parts and hot components from accidental contact. As a result, users can experiment with a wider range of materials, including those that require specific temperature settings to prevent warping and other common issues.

When considering specifications, several features stand out in the best enclosed 3D printers. Print volume is a critical factor; a larger build area allows for the creation of bigger and more complex designs. Additionally, look for printers equipped with advanced hotend technology, which can handle high-temperature filaments while maintaining precision. Some models offer intuitive touchscreen interfaces and connectivity options such as Wi-Fi or USB, enhancing user experience. Other vital aspects include the quality of the frame and construction, which contribute to stability during printing, and filtration systems that help manage fumes generated during the process. Together, these specifications create a robust environment for safe and efficient 3D printing.

User Reviews and Feedback on Enclosed 3D Printers

User reviews play an essential role in assessing the performance and reliability of enclosed 3D printers. These printers are designed to maintain a controlled environment, which not only enhances print quality but also minimizes the risk of warping and other issues associated with temperature fluctuations. According to a recent industry report by Wohlers Associates, the demand for enclosed 3D printers has surged by over 30% in the past few years, reflecting the growing awareness among users of the benefits these machines offer. Feedback highlights that users appreciate the increased safety measures, especially when printing with materials prone to emitting toxic fumes or when operating around children and pets.

Furthermore, user reviews commonly emphasize the importance of build quality and ease of use in enclosed 3D printers. A survey conducted by 3D printing media platforms found that over 60% of users noted improved print consistency and lower failure rates with enclosed models. Many users reported that the ability to maintain a stable printing environment dramatically reduced the instances of failed prints compared to non-enclosed alternatives. Additionally, comments regarding the noise level are frequently mentioned, as enclosures often help dampen sound, making these printers more suitable for home and office use. As the enclosed 3D printer market expands, understanding user experiences is crucial for potential buyers aiming to invest in machines that truly deliver on safety and high-quality production.

Maintenance and Care Tips for Enclosed 3D Printers

When it comes to maintaining an enclosed 3D printer, regular care is essential for ensuring both safety and optimal performance. First and foremost, always keep the printer clean. Dust and debris can accumulate, affecting the printer's mechanisms and the quality of your prints. A soft cloth can be used to wipe down exterior surfaces, while an air compressor or a soft brush can help remove particles from the interior.

Another important aspect of maintenance is the regular inspection of moving parts. Lubricate any railings and lead screws to prevent wear and tear, promoting smoother operation over time. Make sure to check the alignment of the print bed, as a level surface is crucial for achieving high-quality prints. Poor alignment can lead to adhesion issues and an overall disappointing final product.

Lastly, keeping the enclosed environment well-ventilated is crucial, even when it is designed to contain fumes. Consider adding a small fan or ensuring that filters are regularly replaced to mitigate any potential build-up of harmful particles. Regular ventilation not only enhances safety but also contributes to better print results, as some filaments perform better in stable temperature environments. By following these maintenance tips, you can extend the lifespan of your enclosed 3D printer while ensuring that it operates safely and effectively.

Related Posts

-

7 Essential Tips for Choosing the Best High Temperature 3D Printer

-

Ultimate Guide to Choosing the Best Enclosed 3D Printer for Your Business Needs

-

Ultimate Checklist for Choosing the Best Enclosed 3D Printer for Your Business Needs

-

Navigating Export Certifications for the Best Home 3D Printer and What You Need to Know

-

Market Forecast for High End 3D Printers in 2025 and How to Choose the Right One for Your Business

-

Quality Enclosed 3D Printers from China: Your Trusted Partner for Global Success