What is an Enclosed 3D Printer and Why You Should Consider One

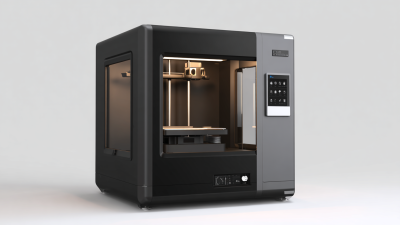

The advancement of 3D printing technology has revolutionized how we create and manufacture products, leading to innovative applications across various industries. Among the different types of 3D printers available, the enclosed 3D printer has garnered significant attention due to its unique features and benefits. Unlike traditional open-frame printers, an enclosed 3D printer is designed with a protective casing that helps to maintain a stable environment for the printing process. This creates an optimal setting for a wide range of materials and significantly enhances print quality.

An enclosed 3D printer offers numerous advantages that can greatly benefit hobbyists, educators, and professionals alike. It not only minimizes the risk of warping and layer separation by maintaining consistent temperature but also ensures safety during the printing process, especially when working with high-temperature materials. Additionally, the enclosed space limits external factors such as dust and drafts, helping users achieve more reliable and accurate prints. As the demand for high-quality, intricate designs increases, understanding the value of an enclosed 3D printer becomes essential for anyone looking to elevate their 3D printing experience.

What is an Enclosed 3D Printer?

An enclosed 3D printer is a type of 3D printer that features a fully enclosed build chamber. This design serves several purposes, primarily to create a controlled environment for the printing process. The enclosure helps maintain a stable temperature, minimizing the risk of warping or other issues that can arise from fluctuating ambient conditions. It also protects the print from contamination and physical disturbances, allowing for higher print quality and reliability.

When considering an enclosed 3D printer, it's important to note the advantages it provides. The enclosed chamber can significantly improve the printer's ability to handle various materials, especially those that are temperature-sensitive. Additionally, it enhances safety by preventing access to hot components, making it a suitable choice for educational environments or homes with children.

Tips: When using an enclosed 3D printer, ensure proper ventilation if you're working with materials that emit fumes during printing. Also, regularly check the interior for any buildup of residue or dust, as this can affect print quality. Finally, take advantage of the stable environment by experimenting with different filament types to discover new printing possibilities.

An Overview of Enclosed 3D Printers

This chart provides a comparative analysis of various dimensions relevant to enclosed 3D printers, highlighting factors such as price range, build volume, print speed, temperature range, and noise level, which are essential considerations for potential buyers.

Key Features of Enclosed 3D Printers

Enclosed 3D printers offer several key features that enhance the printing experience and expand the range of materials that can be effectively used. One major advantage is the controlled environment they provide. Enclosed printers maintain stable temperature conditions, which significantly reduces the risk of warping and improves layer adhesion. This is particularly crucial for high-performance thermoplastics, such as ABS and Nylon, which are prone to deformation in fluctuating temperatures. According to a report by Wohlers Associates, about 40% of 3D printing failures can be attributed to environmental factors, highlighting the importance of a controlled setup.

Another essential feature of enclosed 3D printers is enhanced safety and odor management. These printers often come equipped with HEPA filters or activated carbon filters that help to eliminate harmful fumes released during printing, especially when using certain plastics. A study published in the Journal of Occupational and Environmental Hygiene indicated that proper ventilation and filtration systems can reduce exposure to volatile organic compounds (VOCs), making enclosed 3D printers a safer option for home and educational settings. Furthermore, the enclosure protects users from moving parts and hot surfaces, significantly lowering the risk of accidents during operation.

In addition to these features, enclosed 3D printers typically offer improved noise reduction, allowing for quieter operation compared to their open-frame counterparts. As the market for 3D printing continues to grow, with a projected compound annual growth rate of 23% from 2021 to 2028, enclosed models are increasingly being recognized as a valuable investment for both hobbyists and professionals seeking to enhance their printing capabilities.

Advantages of Using Enclosed 3D Printers

Enclosed 3D printers offer a unique set of advantages that can significantly enhance your printing experience. One of the primary benefits is temperature regulation. These printers maintain a stable environment, which is crucial for materials like ABS and nylon that tend to warp or crack when exposed to fluctuating temperatures. By reducing drafts and temperature changes, enclosed printers help ensure consistent layer adhesion, resulting in higher-quality prints.

Another notable advantage is improved safety. Enclosed printers reduce the risk of accidents, especially in homes or schools where children or pets are present. The closed design minimizes direct contact with hot components and moving parts, creating a safer workspace. Furthermore, an enclosed setup helps contain odors and fumes that can be emitted during the printing process, making the air quality safer and more pleasant.

Tips for choosing an enclosed 3D printer include evaluating the size of your typical projects to ensure the printer's build volume meets your needs. Additionally, consider features like built-in filtration systems or monitoring capabilities that can further enhance safety and print quality. Finally, look for models that offer easy access for maintenance, ensuring that your machine remains in optimal condition for all your future printing endeavors.

What is an Enclosed 3D Printer and Why You Should Consider One - Advantages of Using Enclosed 3D Printers

| Feature | Description | Advantages |

|---|---|---|

| Temperature Control | Maintains a stable temperature during printing. | Improves print quality and reduces warping. |

| Filament Compatibility | Can handle a wider range of materials. | Allows users to experiment with advanced filaments like ABS and Nylon. |

| Safety | Enclosed design protects users from hot components. | Provides a safer printing environment, especially in homes with children or pets. |

| Reduced Noise | Enclosure dampens the noise from the printer. | Creates a more pleasant working environment. |

| Cleanliness | Protects printed objects from dust and debris. | Results in higher-quality finished products. |

| Temperature Stability | Prevents drafts from affecting the print. | Essential for consistent layer adhesion. |

Applications and Use Cases for Enclosed 3D Printers

Enclosed 3D printers are increasingly gaining traction in various sectors due to their distinct advantages in specific applications. One of the primary use cases is in educational institutions, where these printers provide a safe and controlled environment for students to explore additive manufacturing techniques. The enclosed design minimizes noise and odors, making it conducive for classrooms while providing a secure space to experiment with different materials. This feature is particularly beneficial when printing with higher-temperature filaments that require stable thermal conditions for optimal results.

Another significant application of enclosed 3D printers is in industries that require precision and consistency. For example, in the field of prototyping and product development, enclosed printers can create parts with enhanced mechanical properties and reduced warping. These printers are also invaluable in producing functional prototypes and end-use parts where the quality and reliability of the printed object directly impact the product’s performance. Furthermore, the controlled environment allows for the use of advanced materials that can withstand heat and other environmental factors, making them ideal for automotive and aerospace applications.

Factors to Consider When Choosing an Enclosed 3D Printer

When selecting an enclosed 3D printer, there are several crucial factors to consider. First and foremost, the printer's build volume is essential. A larger build volume allows for greater versatility in the types of projects you can undertake, accommodating everything from small prototypes to larger models. Furthermore, consider whether the printer's design allows for easy access to its interior, which is important for maintenance and material loading.

Another important aspect is the printer's thermal capabilities. Enclosed printers help maintain a stable temperature, which is critical when printing with materials that are sensitive to temperature changes, such as ABS or Nylon. Look for models that feature effective ventilation systems to manage the heat while ensuring that safety protocols are in place. Lastly, check for the quality of the enclosure itself; it should provide robust insulation against external conditions to maintain an optimal printing environment. A well-designed enclosure can significantly enhance print quality and reliability, making it a key factor in your decision-making process.

Related Posts

-

What is a High End 3D Printer and How It Transforms Your Creations

-

How to Choose the Best Professional 3D Printer for Your Business Needs

-

7 Essential Tips for Choosing the Best High Temperature 3D Printer

-

Ultimate Guide to Choosing the Best Enclosed 3D Printer for Your Business Needs

-

The Future of Creating Innovative Solutions with the Best 3D Machine Printer

-

Ultimate Checklist for Choosing the Best Enclosed 3D Printer for Your Business Needs