Exploring Distinct Features of Industrial 3D Printers and Their Applications in Manufacturing

In recent years, the manufacturing landscape has undergone a significant transformation, notably driven by the advancements in industrial 3D printers. According to a report by SmarTech Analysis, the industrial 3D printing market is projected to reach $11.9 billion by 2027, reflecting a compound annual growth rate (CAGR) of 26.4%. This rapid growth is attributed to the increasing demand for customized production and the efficiency offered by these cutting-edge machines. Industrial 3D printers not only enable manufacturers to create complex geometries with reduced material waste but also facilitate rapid prototyping and shorter lead times, essential in today's fast-paced market. As China continues to position itself as a high-quality manufacturing hub, the role of industrial 3D printing becomes increasingly critical in delivering superior products tailored to global needs, marking a pivotal shift towards sustainable and innovative manufacturing practices.

Key Innovations in Industrial 3D Printers Transforming Manufacturing Processes

Industrial 3D printers have undergone remarkable innovations that are reshaping manufacturing processes across various sectors. Recent data from a report by Wohlers Associates indicates that the global 3D printing market is projected to grow from $12.6 billion in 2020 to $34.8 billion by 2026, reflecting a compound annual growth rate (CAGR) of 18.3%. Such growth is fueled by technological advancements in materials science and printer capabilities, enabling manufacturers to produce complex geometries and lightweight components that were previously impossible with traditional manufacturing methods.

Key innovations such as multi-material printing and enhanced additive manufacturing techniques are driving these transformations. For instance, the adoption of metal 3D printing technologies has increased, with the market for metal additive manufacturing expected to reach $6.5 billion by 2025, according to a report by MarketsandMarkets. This shift not only allows for the production of intricate metal parts with reduced waste but also accelerates the prototyping process, resulting in shorter time-to-market for new products. Furthermore, advancements in software for design optimization and real-time monitoring are empowering manufacturers to streamline their production processes while ensuring higher quality and consistency in outputs.

Emerging Applications of Industrial 3D Printing Across Various Sectors

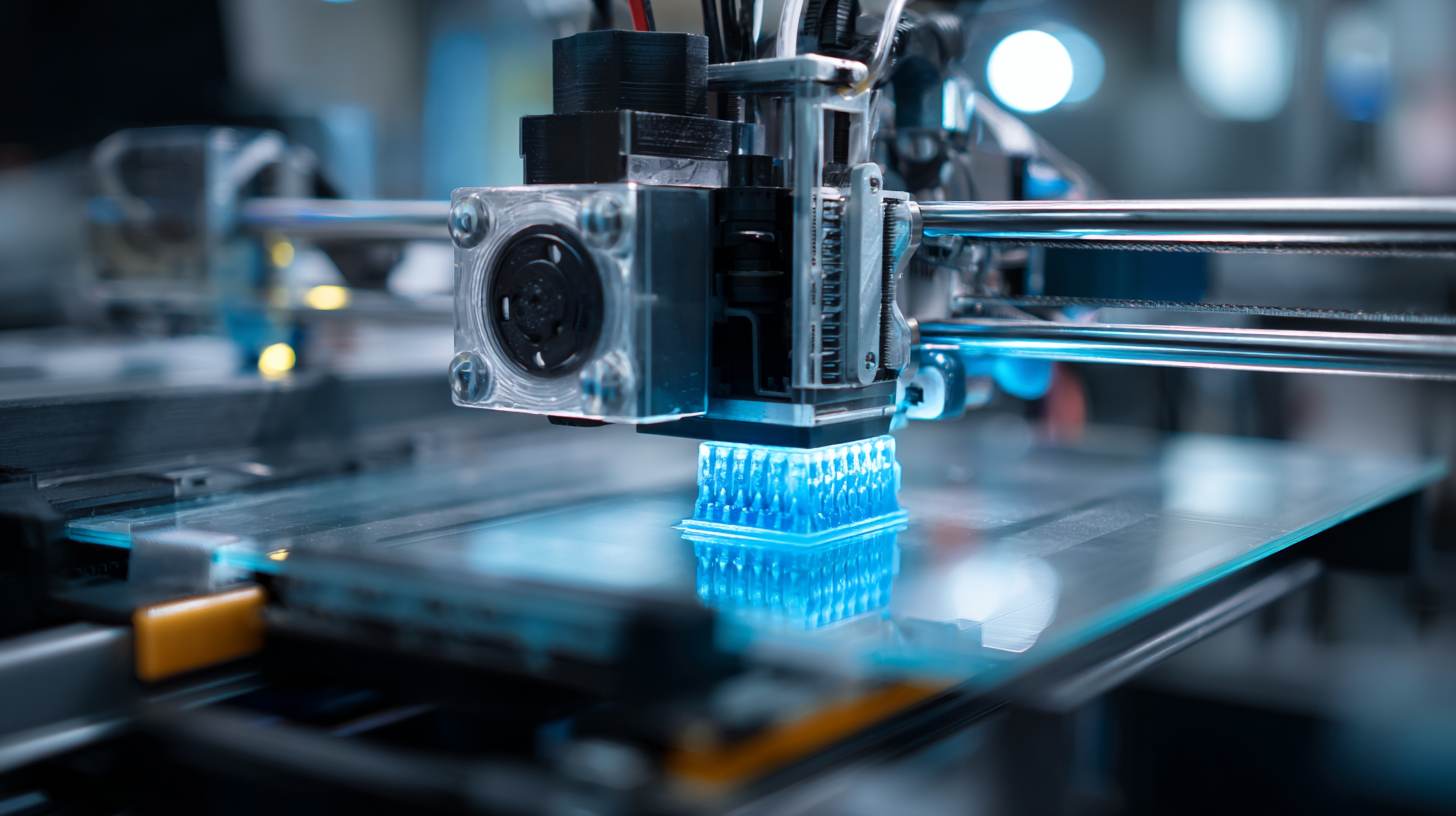

The application of industrial 3D printing is rapidly expanding across various sectors, driven by innovative technologies such as Fused Deposition Modeling (FDM). The FDM market is projected to soar from $18.58 billion in 2024 to $59.96 billion by 2034, reflecting the growing demand for additive manufacturing in diverse industries. This technology is particularly beneficial in construction, where new prototyping methods for cementitious materials are being developed. By utilizing 3D printing, manufacturers can achieve unprecedented efficiency and cost-effectiveness in creating complex structures.

In aerospace, automotive, and medical fields, 3D printing with fiber-reinforced composites is revolutionizing product development. This method allows for the design of lightweight, durable components tailored to specific functional requirements. As the Additive Manufacturing market is expected to surpass $90 billion by 2033, it signifies the critical role that 3D printing will play in modern manufacturing processes.

**Tips:** To maximize the benefits of industrial 3D printing, companies should invest in training personnel on advanced printing techniques and materials. Additionally, staying updated with the latest technological advancements can help businesses remain competitive. Finally, collaborating with experts in prototyping and design can enhance product innovation and minimize production timelines.

Comparative Analysis of Different Types of Industrial 3D Printers

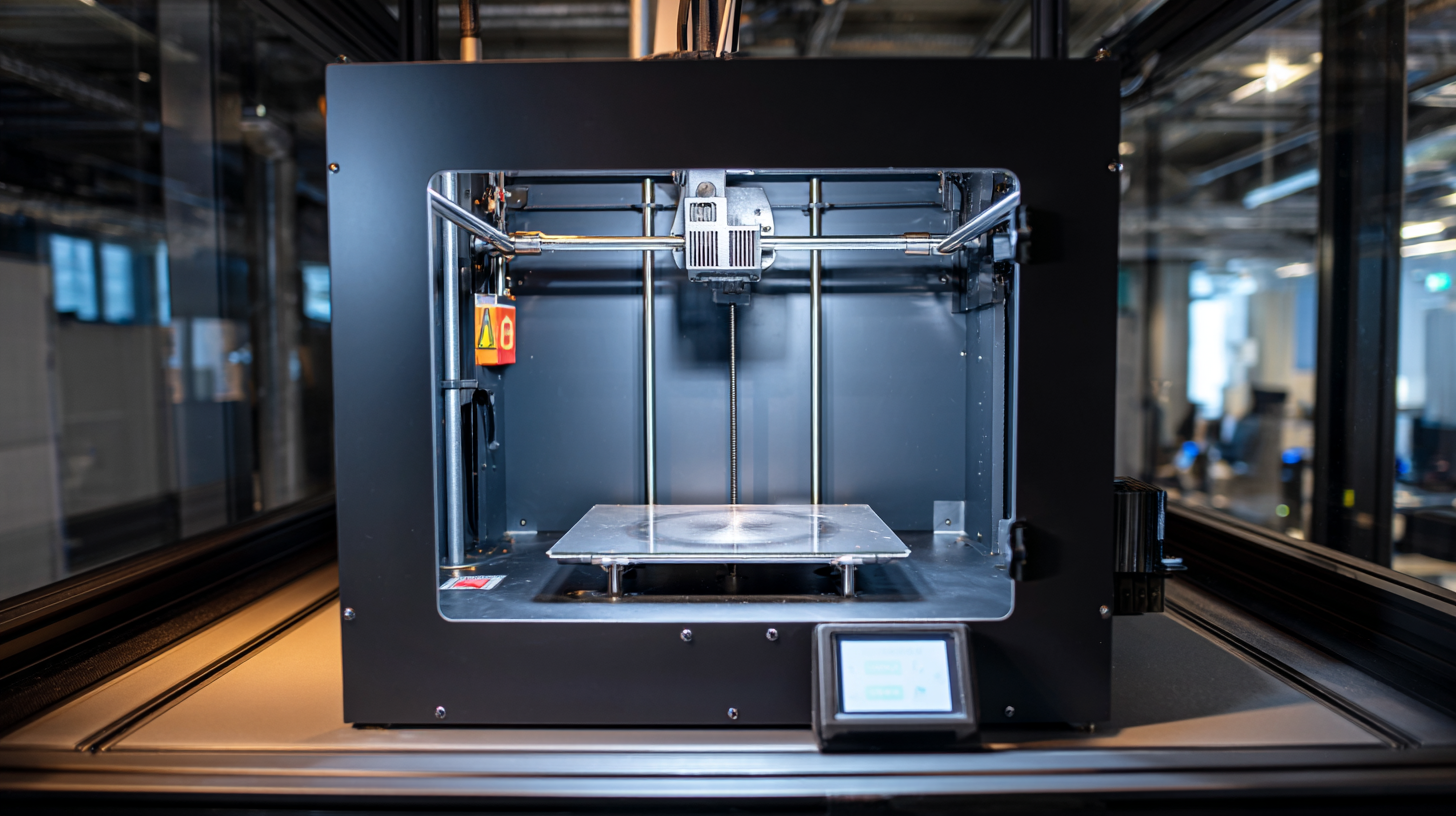

In the realm of manufacturing, industrial 3D printers stand out through their distinct features and capabilities tailored for various applications. The three main types—Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS)—each serve unique purposes, making them crucial to different sectors. According to a report by MarketsandMarkets, the industrial 3D printing market is expected to grow from $6.4 billion in 2021 to $23.3 billion by 2026, reflecting the growing reliance on these technologies.

FDM printers are favored for their affordability and versatility, ideal for prototyping and small-scale production. In contrast, SLA printing offers superior detail and surface finish, making it the go-to solution for intricate designs, particularly in the dental and jewelry industries. SLS, meanwhile, excels in producing complex geometries using metal and nylon powders, which are vital for parts requiring high strength and durability. This diversity showcases the multifaceted roles these printers play in enhancing efficiency and innovation in manufacturing.

**Tips:** When selecting an industrial 3D printer, consider your specific production needs, including material requirements and desired print quality. Investing in a printer that aligns with your workflow can significantly optimize both time and resources. Additionally, staying updated with technological advancements in 3D printing can provide your business with a competitive edge in the manufacturing landscape.

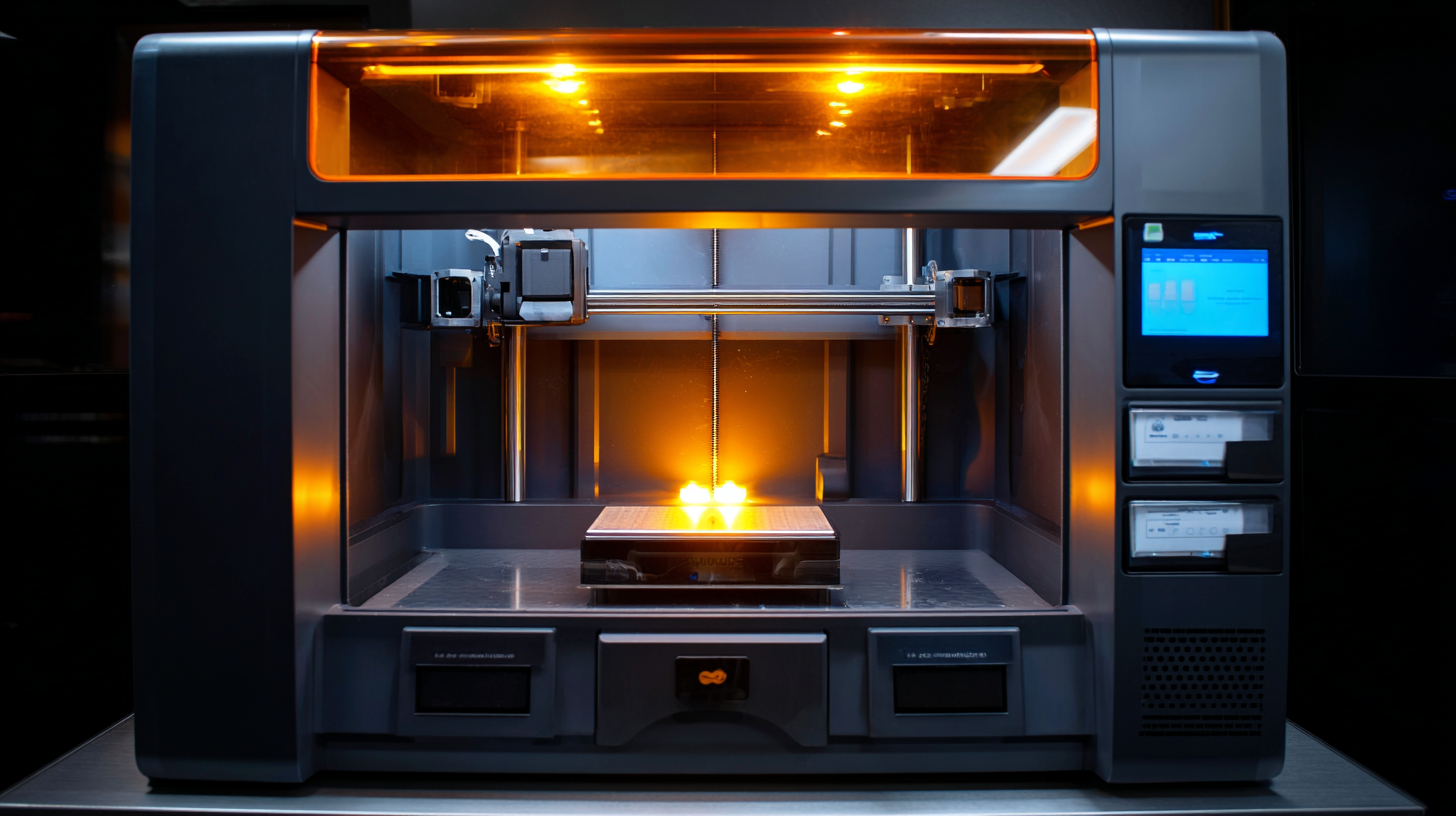

Future Trends in 3D Printing Technology Shaping the Manufacturing Landscape

The landscape of manufacturing is significantly being reshaped by advancements in 3D printing technology. According to a recent report by Wohlers Associates, the 3D printing industry is projected to grow to $49 billion by 2025, indicating a robust trend towards increased adoption in diverse sectors. One of the most notable trends is the rise of industrial-grade 3D printers, which offer distinct features such as higher precision, larger build volumes, and the ability to produce complex geometries with minimal waste. These features enable manufacturers to innovate rapidly and reduce lead times, a critical factor in today’s competitive market.

Future trends also highlight the integration of artificial intelligence and machine learning into the 3D printing process. This integration can optimize production workflows, enhance quality control, and streamline design processes, leading to more efficient manufacturing systems. A study by the Gartner Group predicts that by 2024, 70% of organizations will be utilizing AI to improve supply chain decisions, significantly impacting how products are designed and produced. As these technologies converge, the potential for customizing products at scale while maintaining cost-effectiveness becomes increasingly attainable, marking a transformative phase in manufacturing methods.

How to Choose the Right Industrial 3D Printer for Your Business Needs

When choosing the right industrial 3D printer for your business needs, it's essential to evaluate various factors that align with your goals and production requirements. Consider the specific applications you intend to use the printer for, whether it's prototyping, manufacturing end-use parts, or creating complex geometries. Different printers offer varied capabilities, such as material compatibility and layer resolution, which can significantly impact the final product quality.

**Tip:** Always assess the type of materials you plan to use in your production process. Some printers are limited to specific types, while others can handle a broader range, including plastics, metals, and composites. This flexibility may be crucial as your business evolves.

Another key consideration is the scalability of the printer. As the 3D printing market is expected to grow substantially, with projections indicating significant increases in market size by 2025 and beyond, it’s wise to invest in a system that can expand with your production needs. Look for printers that offer modular upgrades or improved throughput capabilities to maximize your investment.

**Tip:** Research manufacturers' support and warranty options as well. A reliable support system can make a big difference in minimizing downtime and ensuring your operations run smoothly.

Exploring Distinct Features of Industrial 3D Printers and Their Applications in Manufacturing

| Feature | Description | Applications | Material Compatibility |

|---|---|---|---|

| Build Volume | Size of the printable area, often measured in cubic centimeters. | Large-scale parts for aerospace, automotive, and industrial applications. | Plastics, metals, composites. |

| Printing Speed | Rate at which the printer can produce items. | Prototyping, rapid manufacturing. | PLA, ABS, Nylon. |

| Technology Type | Different methods used for 3D printing, such as FDM, SLA, SLS. | Detailed models, functional prototypes. | Resins, powders, filaments. |

| Precision | The accuracy and detail of the printed objects. | Medical devices, intricate designs, custom tooling. | Metals, specialized polymers. |

| Post-Processing | Finishing steps required after printing to achieve desired properties. | Final designs, production-ready parts. | All materials depending on post-process. |