How to Choose the Right Industrial Metal 3D Printer for Your Manufacturing Needs: Key Factors and Insights

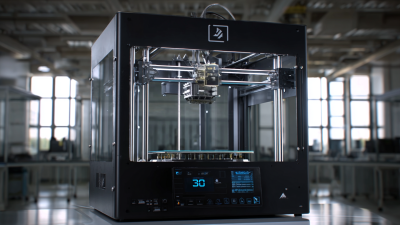

As the manufacturing landscape evolves, the adoption of advanced technologies becomes paramount for staying competitive. Among these innovations, the industrial metal 3D printer has emerged as a game-changer, enabling companies to enhance production efficiency and attain greater design flexibility.

According to a recent report from Wohlers Associates, the metal 3D printing market is projected to reach $5.1 billion by 2025, demonstrating a compound annual growth rate (CAGR) of 23.5%. This rapid growth is indicative of the increasing reliance on additive manufacturing solutions in various sectors, from aerospace to automotive.

However, selecting the right industrial metal 3D printer is a critical decision that requires careful consideration of multiple factors, including material compatibility, build size, and production speed. Understanding these key insights can empower manufacturers to make informed investments that align with their unique operational needs and long-term objectives.

Understanding Your Manufacturing Requirements for Metal 3D Printing

When considering metal 3D printing for manufacturing, understanding your specific requirements is paramount. The global metal 3D printing market is projected to reach $7.33 billion by 2025, growing at a CAGR of 24.5% from 2020 to 2025, according to a report by MarketsandMarkets. This growth underscores the necessity for manufacturers to carefully evaluate their production needs, including the types of materials required, the desired mechanical properties, and the precision necessary for their applications.

One crucial aspect to consider is the intended application of the printed metal parts. Industries such as aerospace and automotive demand high-strength components that can withstand extreme conditions. A study by Wohlers Associates highlights that 58.5% of all additive manufacturing applications are within these high-demand sectors. By thoroughly understanding the specific parameters and certifications required for these sectors, manufacturers can choose 3D printers that are not only capable of producing the necessary quality but also compliant with industry standards, ultimately leading to sustainable and efficient production processes.

Key Considerations When Selecting Materials for Metal 3D Printing

When selecting materials for metal 3D printing, several key factors come into play that can significantly impact the overall quality and functionality of the end product. First and foremost, the material's mechanical properties, such as tensile strength, ductility, and hardness, must align with the intended application. Different projects may require materials that can withstand high stress or those that need to be lightweight without compromising strength. For instance, titanium alloys are favored in aerospace applications for their high strength-to-weight ratio, while stainless steels are often used in tooling and fixtures due to their wear resistance.

In addition to mechanical properties, the material’s ease of processing is critical. Certain metals, like aluminum, can be difficult to print due to their thermal properties, leading to warping or defects. Therefore, compatibility with specific 3D printing technologies, such as laser powder bed fusion or binder jetting, should also be considered. Furthermore, the availability and cost of materials can influence decisions; scarce metals might be less feasible for larger production runs.

Ultimately, understanding these material characteristics helps manufacturers make informed choices that align with their specific applications and production goals.

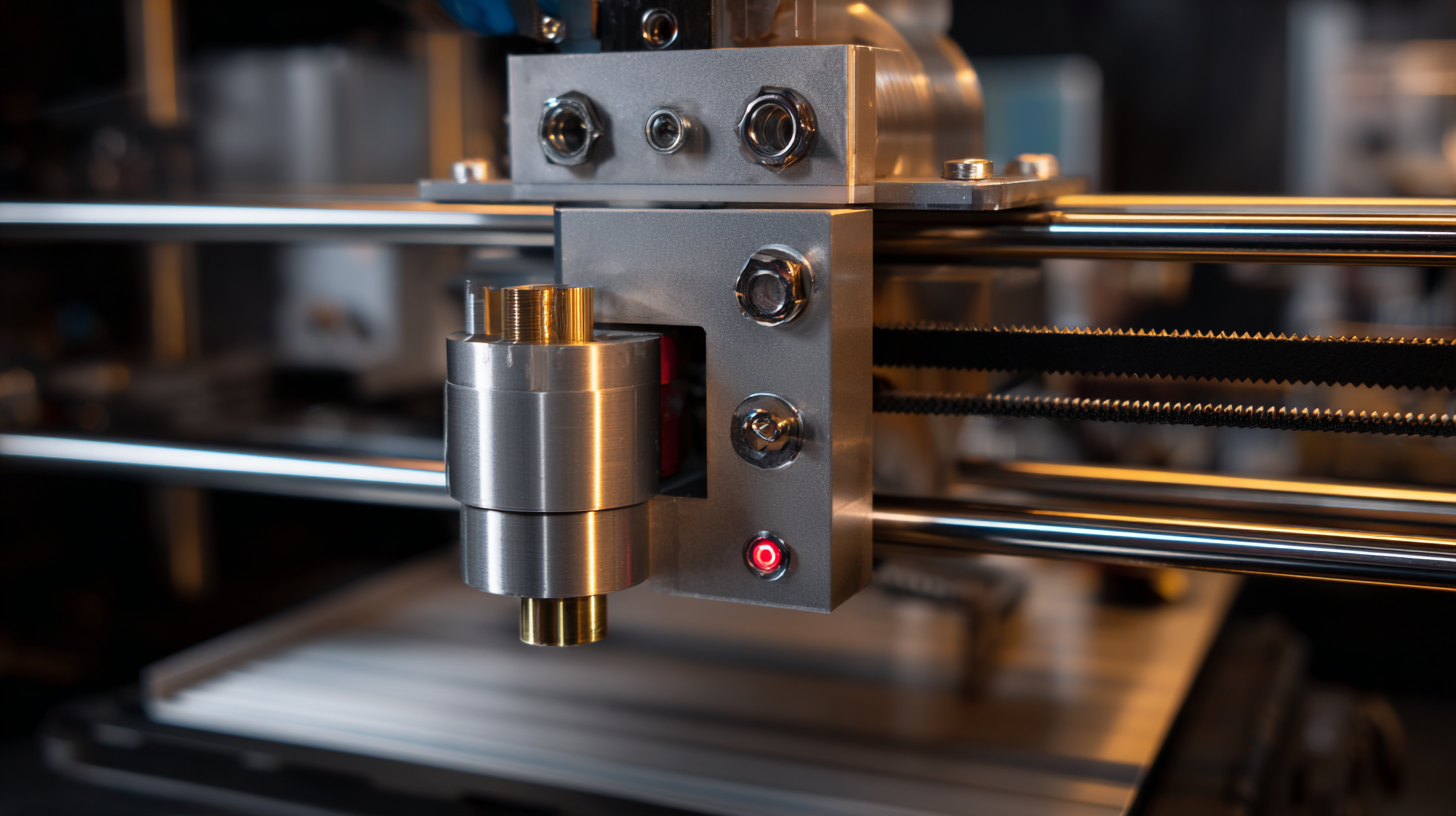

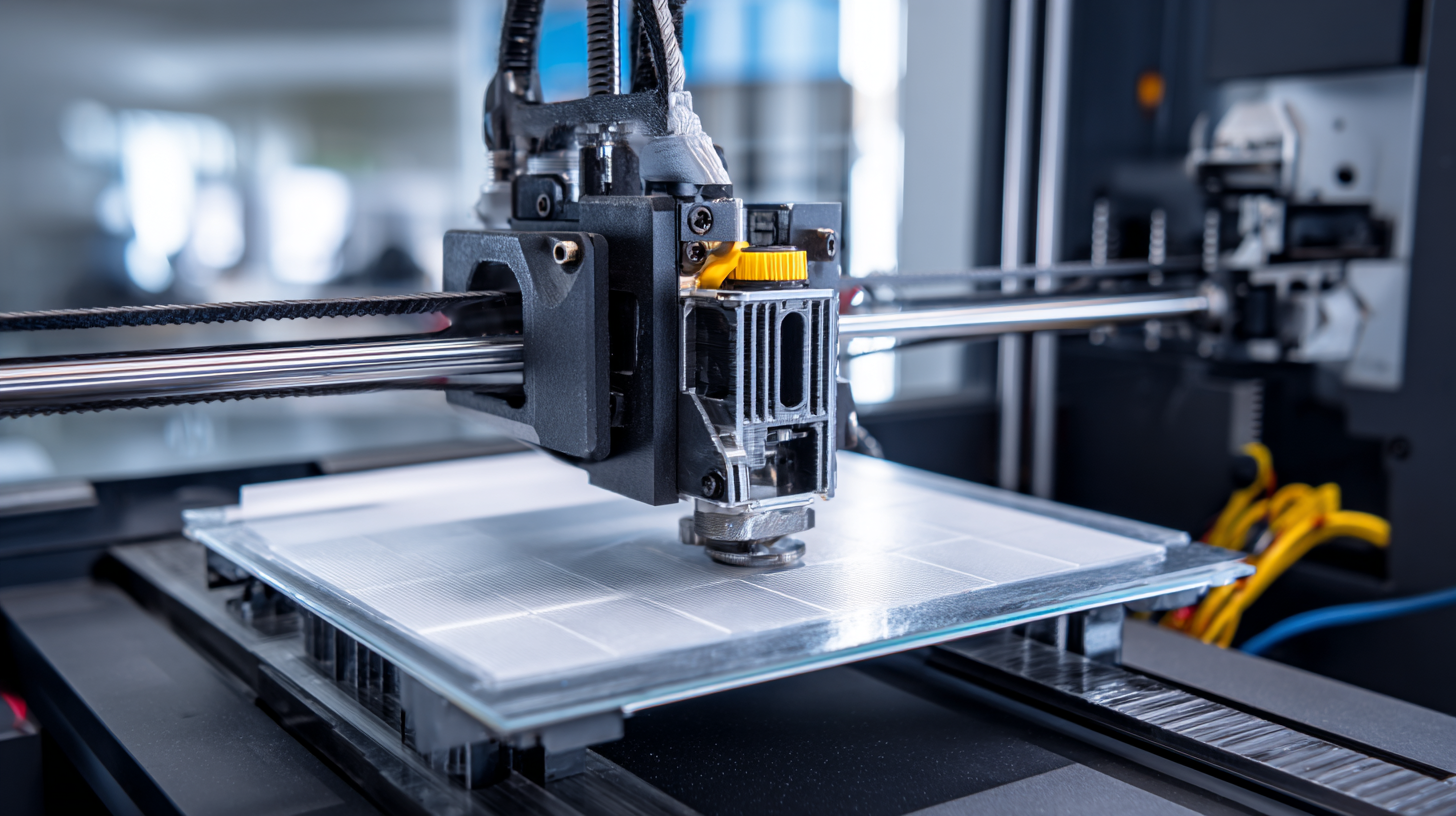

Evaluating the Performance and Specifications of Industrial Metal Printers

When evaluating the performance and specifications of industrial metal 3D printers, several key factors must be considered to ensure they meet manufacturing needs effectively. One of the primary metrics is build volume, which directly impacts the size of components that can be produced. According to a report from Wohlers Associates, larger build volumes are increasingly in demand, with companies seeking systems that can handle larger parts without compromising on print quality.

For instance, printers like the EOS M 400 series can accommodate parts up to 400 x 400 x 400 mm, making them suitable for various industries including aerospace and automotive.

For instance, printers like the EOS M 400 series can accommodate parts up to 400 x 400 x 400 mm, making them suitable for various industries including aerospace and automotive.

Another critical specification is layer resolution and material compatibility. The ability to use multiple materials or customize settings can significantly enhance a printer's versatility. Recent studies show that printers capable of achieving layer resolutions of 20 microns or finer drastically improve details in complex geometries, which is vital for precision engineering applications. Additionally, understanding the materials available for use, such as titanium alloys or stainless steels, allows manufacturers to align their production capabilities with industry standards. Reports indicate that the market for metal 3D printing materials is expected to grow at a CAGR of over 25% through 2025, highlighting the importance of selecting printers that can adapt to evolving material technologies.

Analyzing Cost-Effectiveness and Return on Investment for Your Choices

When selecting an industrial metal 3D printer, cost-effectiveness and return on investment (ROI) are critical considerations that can significantly influence your manufacturing operations. According to a report by SmarTech Analysis, the metal 3D printing market is expected to reach $1.5 billion by 2026, emphasizing the growing trend towards additive manufacturing. Businesses must evaluate not just the initial investment but also the long-term financial implications. A study from Gartner indicates that companies adopting metal 3D printing could see a 30-50% reduction in production costs compared to traditional methods, particularly when factoring in material waste and production time.

Another vital aspect to consider is the potential for increased efficiency and reduced lead times. A report from Wohlers Associates highlights that companies utilizing 3D printing technology can achieve a ROI period as short as 12 months, depending on the scale of production and material used. Therefore, by assessing the overall cost savings from rapid prototyping to final production, manufacturers can better comprehend the viability and sustainability of their investment in metal 3D printing. This data-driven approach allows for strategic decision-making that aligns with both current production needs and future growth opportunities.

Identifying the Best Support and Service Options for Metal 3D Printing Solutions

When selecting an industrial metal 3D printer, the importance of support and service options cannot be overstated. The complexity of metal 3D printing technology demands a reliable service partner who can provide timely assistance during the setup, operation, and maintenance phases. A manufacturer with a robust support system ensures that issues are resolved quickly, minimizing downtime and enhancing productivity. Thus, it's essential to evaluate vendors based on their customer service reputation, response times, and the availability of local support representatives.

Moreover, the training and resources offered by the manufacturer significantly impact the effectiveness of your metal 3D printing operations. Comprehensive training programs empower your team to utilize the equipment efficiently, reducing the potential for errors and optimizing production processes. Additionally, access to extensive documentation, online tutorials, and proactive maintenance options can enhance your troubleshooting capabilities. By considering these support factors, you can ensure that your investment in metal 3D printing technology aligns with your manufacturing needs and operational goals.

| Criteria | Importance Level | Key Features to Look For | Support Options | Service Availability |

|---|---|---|---|---|

| Build Volume | High | Size of parts to be produced | 24/7 Technical Support | Global Availability |

| Material Compatibility | High | Types of metals supported | Material Supply Chain Assistance | Local Service Centers |

| Print Speed | Medium | Layer height and speed capabilities | Startup Support | On-site Support |

| Post-Processing Requirements | Medium | Ease of finishing parts | Training Programs | Responsive Customer Service |

| Cost of Ownership | High | Initial cost, maintenance cost | Financing Options | Warranty Services |

Related Posts

-

20 Key Features of the Best Industrial Metal 3D Printer for Global Buyers

-

What is the Ultimate 3D Printing Solution for Metal Manufacturing

-

Digital Insights and Tips for Choosing the Best Industrial 3D Printer

-

10 Key Factors to Choose the Best 3D Printer for Metal: Insights from 2023 Industry Trends

-

Exploring Distinct Features of Industrial 3D Printers and Their Applications in Manufacturing

-

Unlocking the Secrets to the Best 3D Systems Printers for Your Business Needs